Shipping Cost Optimization Solution for Apparel Retailers

- Overview

- Details

- Case Studies

DIGI's automatic dimensioning and weighing technology provides powerful support for optimizing shipping costs, a key challenge in e-commerce (EC) logistics.

Increases in package delivery fees directly lead to higher costs in EC logistics. This solution efficiently reduces shipping costs for apparel retailers, whose package sizes tend to be large.

Customer Needs

- Want to optimize package delivery costs

- Want hassle-free size measurement of packages

- Overview

- Details

- Case Studies

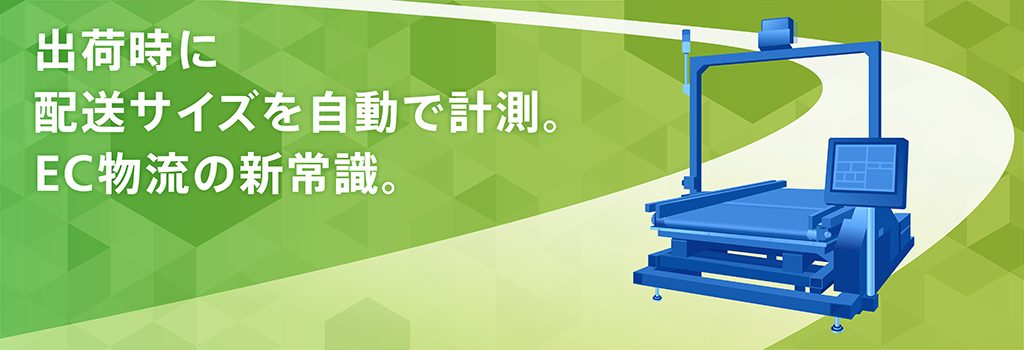

Automatic Size Measurement of Large Numbers of Shipping Packages on a Conveyor

DIGI's automatic in-motion dimensioning weigh scale automatically measures the size and weight of packages before shipping. Simply place the package on the conveyor and the system quickly and accurately captures the dimensions and weight. For the first time in the industry, automatic dimensioning of items with a height as small as 5 mm is possible.

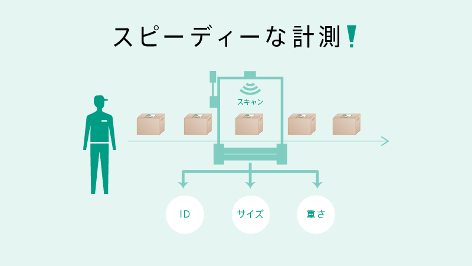

Equipped with an Integrated Barcode Reader

The system scans the barcode printed on the package delivery slip and automatically links the package ID (= invoice number) with the size and weight of the package. Barcode scanning and package dimensioning are processed continuously on a conveyor, for smooth and speedy shipping operations.

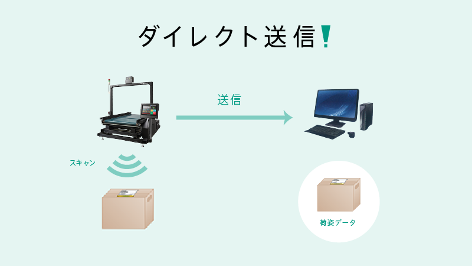

Measurement Data Are Directly Sent to Your PC

Barcode information (package ID), dimensions, and weight data are sent directly to your PC, instantly creating the package data record. This eliminates the need for manually keying in the invoice number and dimensions, preventing input errors. The system provides outstanding support for the tallying process in EC logistics, where speed and accuracy are a must.

SMART QBING streamlines shipping operations, reducing the burden on staff and realizing a variety of operational improvements

Yamada Bee Company, Inc.

Yamada Bee Company develops, manufactures, and sells honey, royal jelly, and other bee products, as well as natural foods, health foods, and cosmetics. It is remaining true to its goal of contributing to harmony between nature and society by taking responsibility for the entire beekeeping process, from production to shipping. The company recently introduced SMART QBING automatic in-motion dimensioning weigh scale to improve efficiency and reduce personnel requirements in its shipping operations.

Reduced workload and improved efficiency

Introducing SMART QBING with the sorting attachment has made it possible to identify the carrier and then do a primary sort by destination, reducing the sorting workload and reducing errors. Staff have commented that with the reduced workload and improved efficiency they can now perform several tasks simultaneously.