感谢您访问我们的网站。现在,我们仅能用英语提供本信息。我们正在不断努力用中文提供更多的内容。感谢您耐心等待!

SMART QBING

This automatic in-motion dimensioning and weighing system offers speedy measurement of package dimensions and weight on a conveyor. Measures items down to 5 mm thickness - an industry first.

SMART QBING is a system designed for logistics centers that fully automates dimensioning and weighing of packages. Get quick and accurate measurements by simply passing the items along on the conveyor. As an industry first, SMART QBING can measure items that are as little as 5 mm thick. In today's busy logistics workplace, pressured by the rapid rise in delivery service use coupled with a troubling increase in re-deliveries due to customer absence, speedy and accurate measurement of package dimensions can dramatically assist in streamlining operations and reducing costs.

Non-stop speedy dimmension and weight measurement

Three built-in scales under the conveyor do the weight measurement. Using a patented weighing algorithm, packages with as little as 40 cm spacing on the conveyor can be accurately weighed one after another at high speed without missing a single item. Combining the 40 cm spacing with SMART QBING's impressive 120 m/minute conveyor speed, you can process up to 9000 cases/hour for an average item length of 40 cm. DIGI has achieved this level of performance because we are a weigh scale manufacturer, and high-speed processing is our strong point.

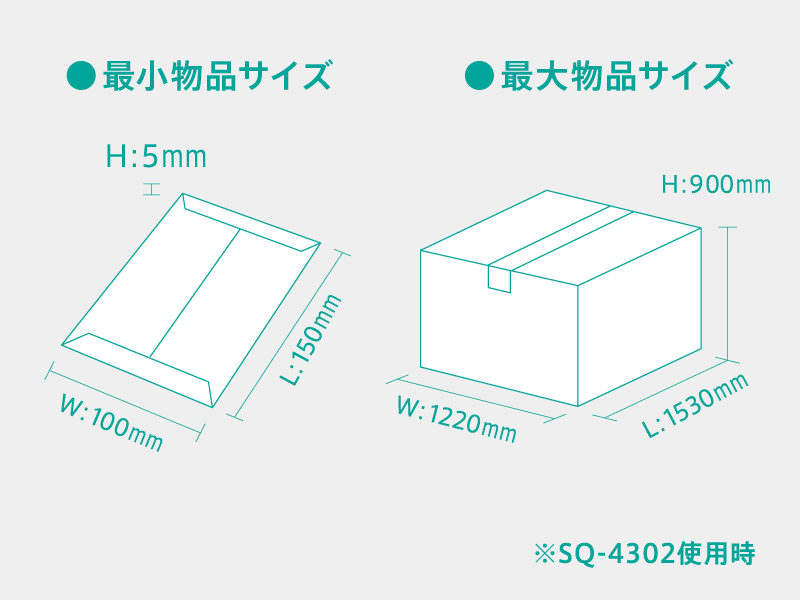

A first for the logistics industry! Measuring packages with 5 mm thickness!

SMART QBING has a high-precision infrared transmission sensor built into its gate sensor, allowing three-dimensional measurements with 5 mm pitch. By adding our Thin Item Detection option, the system can automatically dimension items of as little as 5 mm thick. Conventional systems have only been able to handle items of at least 3 cm thickness. So, being able to automatically measure 5 mm-thick items is truly a first for the industry.

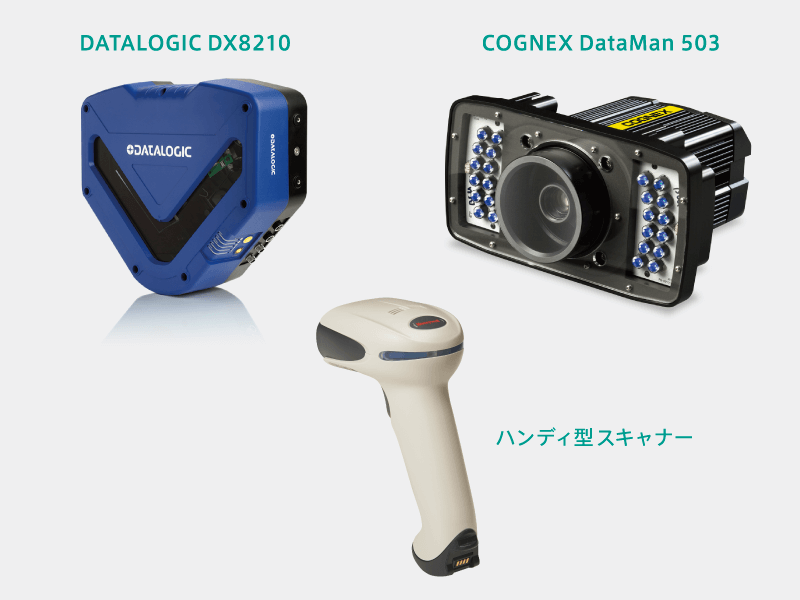

Integrated bar-code scanning

Barcodes are indispensable to logistics operations and SMART QBING has built-in barcode scanning functionality. You can select optional equipment that ranges from manual hand scanners all the way up to high performance automatic scanning directly from the conveyor.

The barcode, dimensions, and weight data are grouped and sent to a host, such as a PC or PLC, making it simple and easy to integrate SMART QBING with warehouse management systems, sorting lines, and shipping operations systems. This, in turn, contributes to logistics cost reductions, lower storage costs, and more effective utilization of warehouse space.

The barcode, dimensions, and weight data are grouped and sent to a host, such as a PC or PLC, making it simple and easy to integrate SMART QBING with warehouse management systems, sorting lines, and shipping operations systems. This, in turn, contributes to logistics cost reductions, lower storage costs, and more effective utilization of warehouse space.

A variety of models to suit the size and application

Choose from three model series with different conveyor sizes according to your item size and installation space requirements: the 60 cm-wide SQ-2000 series, the 90 cm-wide SQ-3000, or the 122 cm-wide SQ-4000 series.

These systems can be flexibly configured to provide dimensions-only, weight-only, or barcode-and-weight-only measurements.

These systems can be flexibly configured to provide dimensions-only, weight-only, or barcode-and-weight-only measurements.