Picking carts with built-in scales enable simultaneous picking and quantity verification

AI picking carts

LogistiekBelangrijkste kenmerken

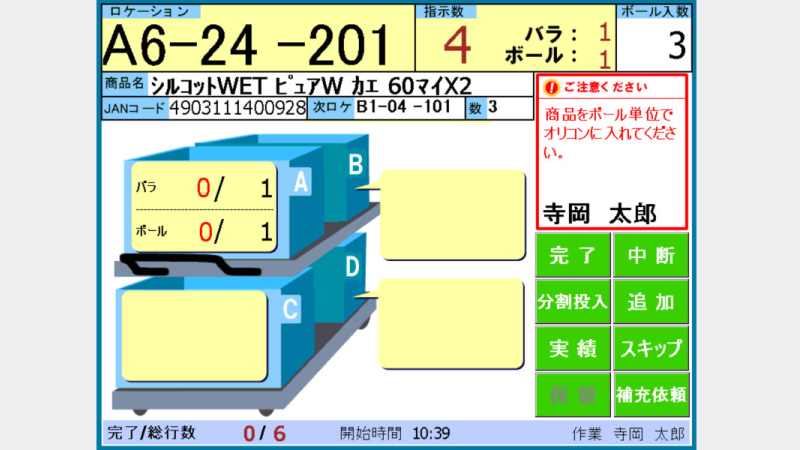

Cart with built-in scale is ideally suited for the most labor-intensive picking work in distribution centers. Contributes to increased productivity by wirelessly communicating with the shipping/receiving management system (IT-Matex III), which verifies quantities picked while simultaneously determining the optimum picking path. Eliminating the need to work with forms such as shipping instructions and minimizing the need for printed labels, this system helps reduce operational costs. Lightweight and compact even with its built-in scales, the cart also excels at navigating aisles.

High-precision loadcell

Accurate quantity verification is achieved by adopting a high-performance load cell (internal resolution: 1/30,000; display resolution: 1/3000) to minimize unit weight errors.

Worker motivation function

An animal character on the display changes to indicate per-hour picking performance. This helps workers increase performance in an enjoyable way.

Simultaneous box/loose verification

Box and loose weights can be registered for each PLU according to packing type. Not only does this facilitate simultaneous picking of boxed and loose items, but it helps keep orders together and makes it easy to tell how many items should be removed from a container to fill an order.

Specificaties

Afmetingen

Specifications

| Model Type |

PKG-4000 Multi-cart (Vertical type) |

PKG-4000F Multi-cart (Front-on type) |

PKG-3100 Single cart |

PKG-3100D Single cart (Detachable type) |

|

|---|---|---|---|---|---|

| Display | 10.4-inch TFT LCD (SVGA) touch panel | ||||

| Wireless communication | Wireless LAN | IEEE802.11b/g | |||

| Scanner | Compatible barcode types | UPC, EAN, JAN, CODE39, ITF | |||

| Operating time (handy scanner) | 45000 scans, charges in 4 hours | ||||

| Printer | Print method | Thermal printer | |||

| Print size | 60 (W) x 120 (L) mm | ||||

| Scales | Maximum load weight | 30 kg | |||

| Display resolution | 1/30,000 | ||||

| Internal resolution | 1/60,000 | ||||

| Number of scales | 4 | 4 | 1 | 1 | |

| Power supply | Continuous operating time | 14 hours or better (front-on type cart) * Varies according to manner used and environment. |

|||

| Type | Ni-MH (Nickel-Metal Hydride Battery) | ||||

| Charging time | 10.5 hours | ||||

| Charging system | DIGI Chain charging (charges up to 5 units at once) | ||||

| Cart | Service temperature | 5 to 35℃ during operation, 0 to 55℃ in storage | |||

| Service humidity | 20 to 85% RH (no condensation) | ||||

| Frame material | Aluminum | ||||

| Dimensions (mm) W x H x D |

570 x 1140 x 1350 | 830 x 1024 x 841 | 570 x 1050 x 1285 | 620 x 1130 x 625 | |

| Weight | 45 kg | 45 kg | 34 kg | 40 kg | |

Variaties

Multi-cart (vertical type)

PKG-4000

Multi-cart (front-on type)

PKG-4000F

Single cart

PKG-3100

Single cart (detachable type)

PKG-3100D

In de praktijk

AI Picking Cart - Picking Cart with Built-in Weigh Scale SPK - High-precision Dimensioning Weigh Scale

Tokyo Logistics Factory Co., Ltd.

The need for inspection and repacking of products before shipping was eliminated, dramatically improving work efficiency and increasing productivity.AI Picking Cart with Built-in Weigh Scale and SPK High-precision Dimensioning Weigh Scale

Keihin Distribution Co., Ltd.

Improved productivity by increasing picking accuracy through double inspection (scanning and weighing) and reducing post-picking inspection work when packaging.FAQ

-

Aside from eliminating storage for forms, what is the advantage of doing away with paper picking lists?Time required to produce lists is eliminated, including printing. Errors in product type, packaging, and quantity that result from misreading lists are also reduced. Further, not having to hold a list leaves both hands free for picking.

-

How much time is needed for charging?About 8 to 9 hours. Time varies somewhat according to type.