A shipping/receiving/inventory management system for keeping track of workplace status in real-time

IT-MatexⅢ

LogisticsMain Features

IT-Matex III is an operations-oriented ERP-type planning system that facilitates workplace-centric management of people and resources. Playing a complementary role in ERP by serving as an interface with the workplace, it resolves a range of issues by enabling more fine-grained inventory control, greater picking productivity, and rationalization of production management.

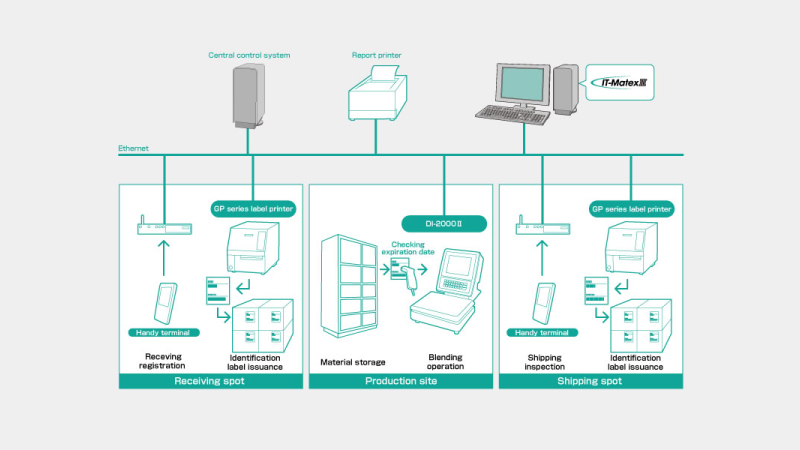

Food production systems

IT-Matex III helps minimize disposal losses through management of inventory and expiration dates. It provides positive prevention of blending errors and timely traceability of lots used.

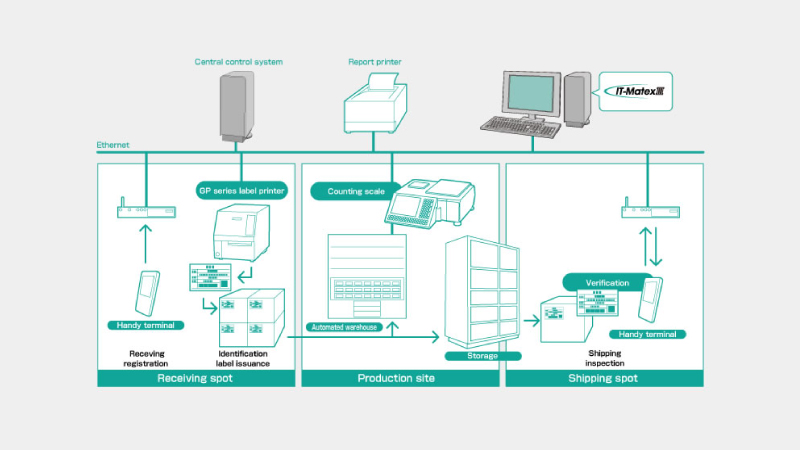

Industrial systems

With IT-Matex III, you can introduce traceability to sorting of parts and components. Besides controlling inventory at the lot and production date level, you can easily track shipment of products by lot.

Distribution center systems

Real-time communication with AI picking carts reduces wasted movement during picking work, helping to increase productivity.

Specifications

Dimensions

IT-Matex III: software operating environment

| Operating system | Windows XP® Professional/ Windows7® Professional |

|---|---|

| Memory | At least 512 MB |

| Display | Windows®-compatible color display (1024x768 or better recommended) |

| Hard disk | Requires a minimum of 200 MB free space |

| Server | Windows® Server 2008 SQL Server 2008 license |

Handy terminal specifications

| Operating system | Windows® Embedded CE6.0 R3 |

|---|---|

| Display | 3.7-inch transmissive color TFT display (VGA, 480x640 dot) |

| Wireless LAN | IEEE 802.11a/b/g-compliant, WPA2-compatible |

| Power supply | Using 1800 mAh lithium-ion battery: About 12 hours, Charging: About 2.5 hours |

| Dimensions (mm) | W: 69 x D: 159 x H: 23 |

| Unit weight | Approx 270 g (including battery) |

| Drop resistance | 1.5m |

| Ingress protection | IP55-compliant |

| Use environment | -5 to 50 degrees C/20 to 80% RH (no condensation) |