Sustainable PET plastic bottle recycling in a compact form factor

DRV-100

RetailMain Features

DRV-100 is a reverse vending machine that significantly reduces the volume of PET plastic drink bottles. Thanks to a newly developed compression mechanism, DRV-100 realizes both space savings and high-quality resource recovery. And, by connecting a loyalty card point server to the unit, customers can collect points as they recycle, so you can attract more customers and increase repeaters. In addition to the standard DRV-100 model, the DRV-100T offers higher storage capacity, which decreases the number times the unit needs to be emptied.

A form factor focused on space savings

With its space-saving design, DVR-100 can fit into small shops and offices, where reverse vending machines typically could not be installed. So, now more recycling stations can be created without having to worry about the location. Additionally, the bottle inlet is located lower down on the unit, so even children can have a chance to enjoy the experience of recycling their PET bottles.

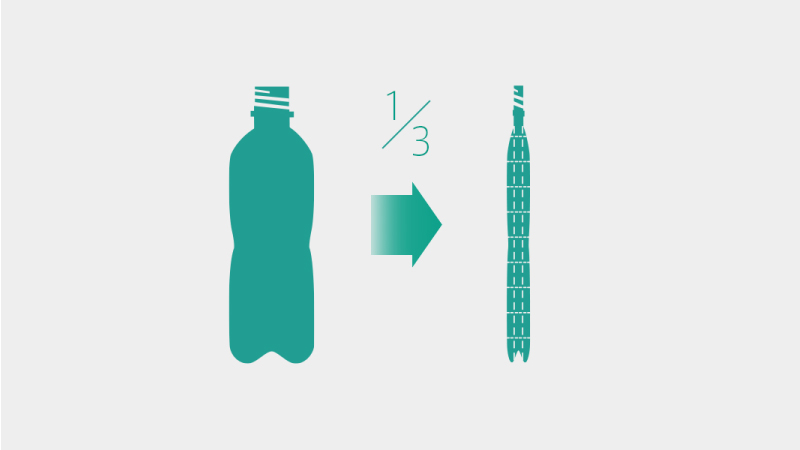

Increases recycle material value through a newly developed compression scheme

A newly developed compression scheme (pre-cutting method) ensures the compressed bottle stays flat after processing. Also, this new method does not rupture the comparatively heavier bottle spout portion, so the value of the recycling material is significantly increased. The unit also has an inlet for bottle caps, which are made of a non-PET plastic, to promote separation of the two materials for recycling.

Promoting recycling awareness (eco-education)

DRV-100 is equipped with a display screen that can show 3R and Bottle-to-Bottle recycling educational content while the bottles are being processed. This offers an excellent opportunity for the machine owner to show that they are actively contributing to the protection of the environment.

Visit the link below to view a concept video for the DRV-100:

IoT support system

DRV-100 offers a wireless router-based IoT support system that lets you comprehensively manage your daily collection numbers. The IoT system supports stable operation by monitoring machine status 24/7/365 and instantly notifying you by email when errors occur or collection bins are full.

Creating a sustainable recycling system with the customer

Installing a PET bottle reverse vending machine in your store not only increases work efficiency, it provides an entry point to Bottle to Bottle*1 recycling. DIGI is contributing to the realization of an SDGs*2 oriented PET bottle recycling scheme that has merit for each and every stakeholder.

*1:A recirculating recycling system where used food-use PET bottles are recycled into new food-use PET bottles.

*2:The 2030 agenda for sustainable development adopted by the United Nations.

Specifications

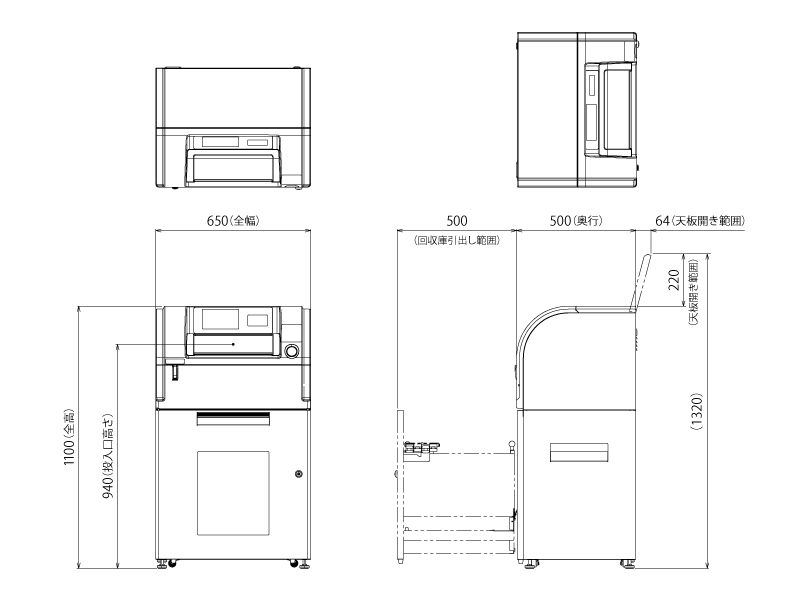

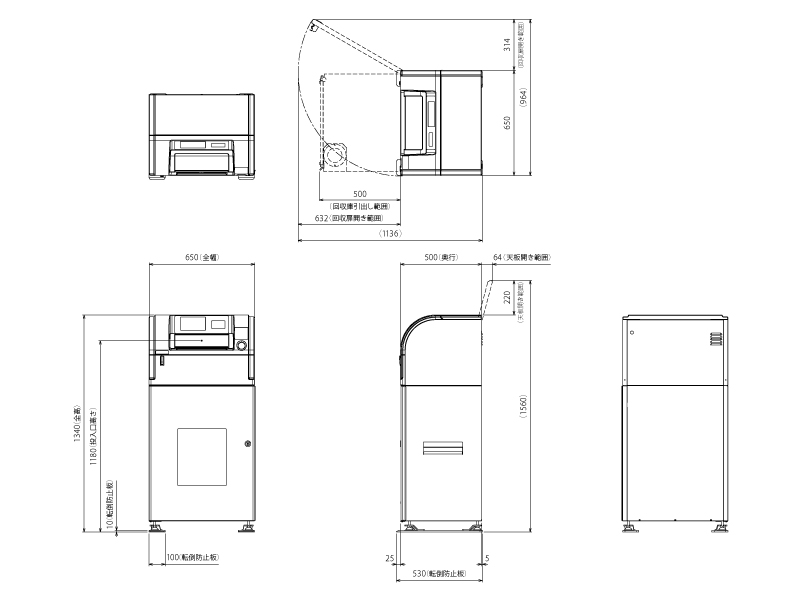

Dimensions

Basic specifications

| DRV-100 | DRV-100T | |

|---|---|---|

| External Dimensions (W × D × H) |

650mm × 500mm × 1,100mm | 650mm × 500mm x1,330mm |

| Net Weight | Approx 149 kg | Approx 172 kg |

| Storage Box Size (W × D × H) |

530mm x 450mm × 440mm (Max) | 525mm x 445mm × 649mm (Max) |

| Collection Bag Capacity (W × D × H) *Estimated Size |

For bottles:100ℓ For caps 180mm × 120mm × 400mm |

For bottles :120ℓ For caps: 180mm × 120mm × 400mm |

| Power Supply Voltage/ Power Consumption |

Single phase 100V / 1.05kW | |

| Power Supply Connector | Flat blade two-pole plug with grounding prong 125V 15A rating | |

| Operating Environment (Temperature/ Humidity) |

0 to 40℃ 90%RH (Max) *with no condensation | |

| Processing Speed | About 10/ min | |

| Compatible Bottle Sizes | φ45 × 116mm – φ120 × 340mm | |

| Operating Noise Level | 68.7dB (Max) | |

| Bottle Material Recognition | Combination of all sensor inputs | |

| Display | 7.0 inch TFT color display | |

| Touch Panel | Resistive pressure-sensitive membrane touch panel | |

| Communications | Wireless mobile router | |

Note: The above specifications are for models sold in Japan.

Variations

Mid-size model

DRV-100T

FAQ

-

How many bottles can be processed in one minute?Ten bottles can be processed in one minute (six seconds per bottle).

-

What types of PET bottles can be processed?The machine can process beverage PET bottles that are up to 340 mm tall and 120 mm in diameter.

Note: The machine may not be able to process certain types of very small PET bottles.