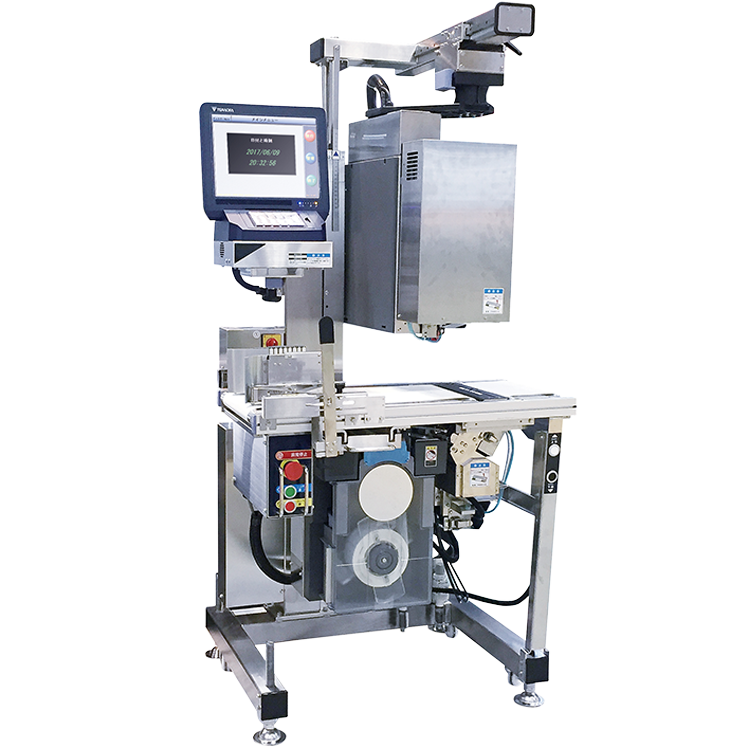

A state-of-the-art general purpose automatic thermal labeler that handles a wide variety of label formats

AP-800

Food IndustryMain Features

AP-800 is an automatic thermal labeler that realizes sophisticated functionality and outstanding operability. Label formats can be easily created on a large-size color display and then printed using simple operations. We completely revamped the basic functionality to allow more accurate and efficient operation in an easy-to-clean, space-saving form factor.

Realizing more advanced labeling

AP-800 realizes improved speed and precision compared to conventional labelers. The top labeler uses a rotating applicator, so a label angle can be set for each master. We also added an array of features to fundamentally improve the performance of the print/apply functionality, to further advance daily labeling operations.

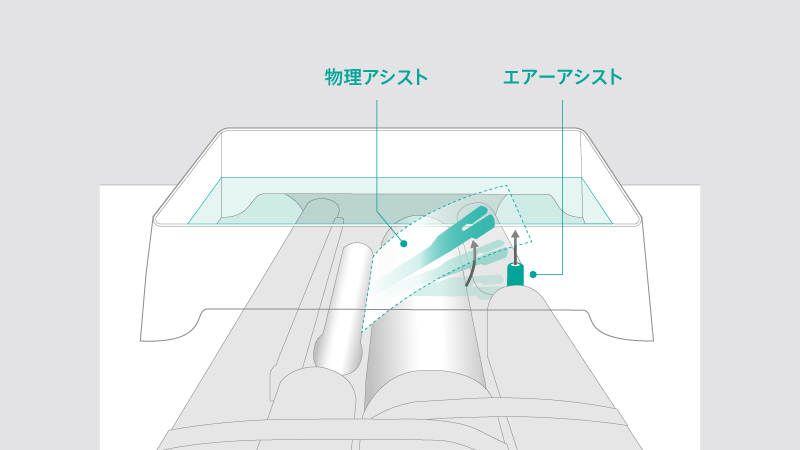

Compatible with raised bottom trays

With tray shapes becoming more varied, certain tray types, such as raised-bottom trays, may pose a challenge when applying a label to the tray bottom. In addition to making the conveyor flat to stabilize tray movement, AP-800 includes two additional mechanisms, a physical assist and an air blow assist, for applying bottom labels. You can select which to use according to the product weight and the shape of the tray bottom; the unit can handle trays with raised bottoms of up to 15 mm.

Easy to replace consumables and easy cleaning!

A dedicated mode for replacing the platen roller has been added, where the roller moves to a position where it can be easily replaced without special tools.

In addition, a flat-panel LCD with excellent visibility and operability is adopted, making cleaning that much easier.

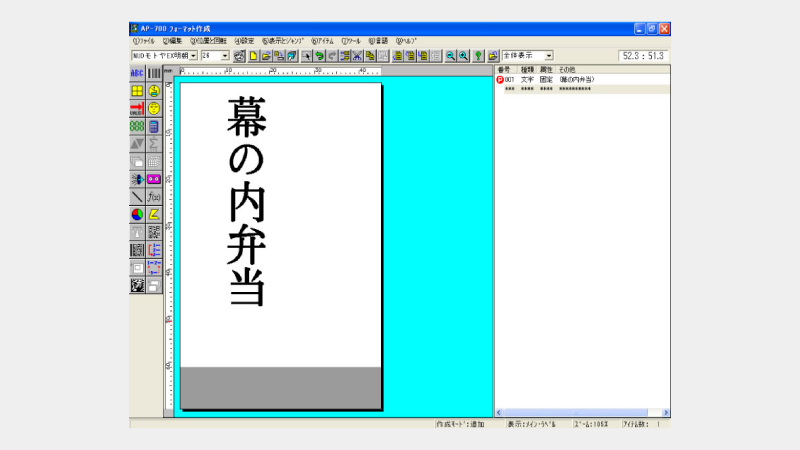

Flexible and easy label design

AP-800 provides dedicated software for customizing label formats that is easy to use even for beginners. You create label formats and a product database on a PC and then transfer the data to the labeler using a USB memory.

Specifications

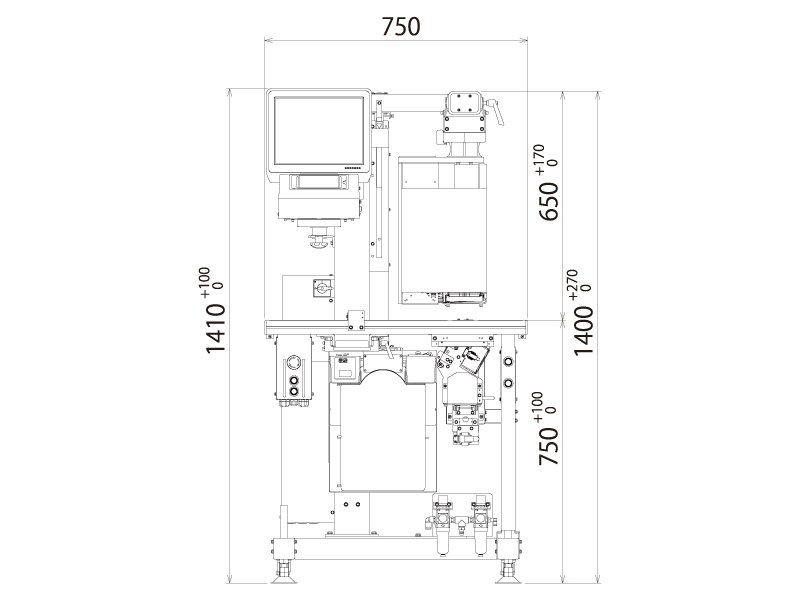

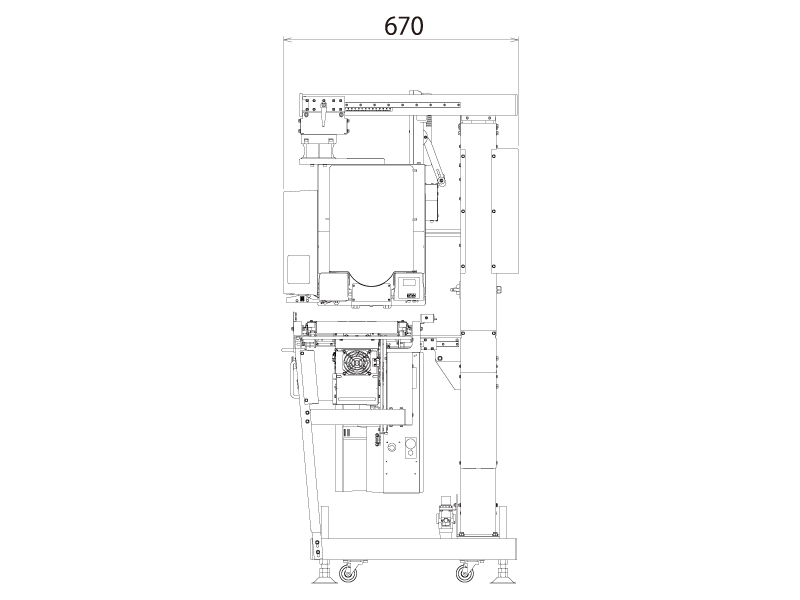

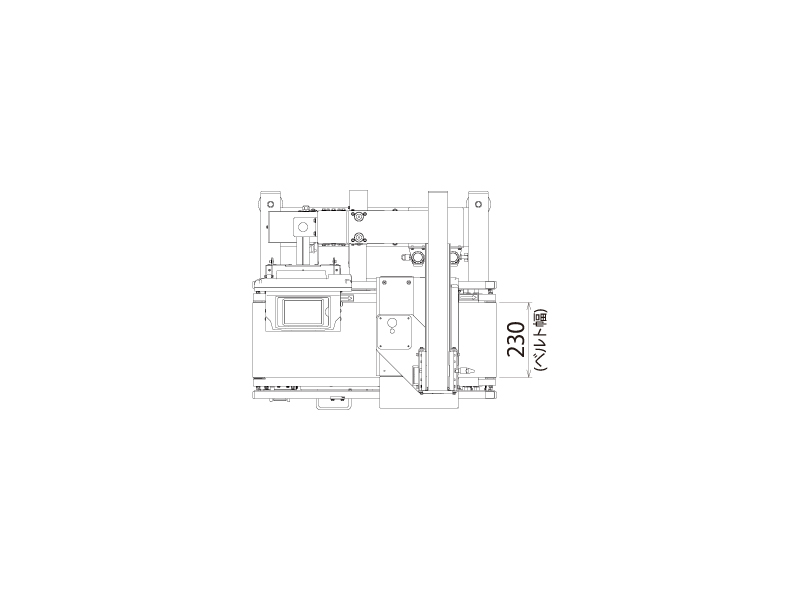

Dimensions

| Label Applicator type | U | UB | B | ||

|---|---|---|---|---|---|

| Printing method | Thermal printing (300dpi) | ||||

| Label print speed | Max. 200 mm/sec. | ||||

| Package size | Width | 50 to 240 mm | |||

| Length | 50 to 350mm | 70 to 350 mm | |||

| Height | 15 to 190 mm | ||||

| Label size | Upper Applicator *Standard applicator |

Width | 40 to 80 mm | ||

| Length | 28 to 100 mm | ||||

| Upper Applicator *Rotary applicator |

Width | 40 to 80 mm | |||

| Length | 28 to 100 mm | ||||

| Bottom Applicator | Width | 40 to 80 mm | |||

| Length | 28 to 130 mm | ||||

| Label outer diameter |

Max. φ190 mm

(Core inner diameter φ76 mm)

|

||||

| Dimensions of main unit | Width | 750 mm | |||

| Length | Standard applicator | 670 mm | 640 mm | ||

| Rotary applicator | 680 mm | ||||

| Height (Min. Height) |

Standard applicator | 1410 mm | 1410 mm | ||

| Rotary applicator | 1550 mm | ||||

| Conveyor Height | 800 mm ± 50 mm | ||||

| Direction of product flow | Right flow or Left flow | ||||

| Power supply | 100V Single phase | ||||

| Power consumption | 235 W | 340 W | 185 W | ||

| Conveyer speed (m/min.) | 5.5 to 50 (Variable) | ||||

| Air consumption | Upper Applicator | Max 1.61 ℓ/ sheet | |||

| Bottom Applicator | Max 2.36 ℓ/ sheet | ||||

| Weight of main unit | 115 kg | 135 kg | 90 kg | ||

| Noise level | Max. 83 dB | ||||

| Operating temperature | 5 ℃ to 35 ℃ (without condensation) | ||||