A state-of-the-art thermal labeler that's helping to make linerless labels a new standard in the food manufacturing industry

HC-800LL

Food IndustryMain Features

Five years have passed since the launch of HC-700LL, the industry's first automatic labeler with linerless label support that includes an automatic cutting function, which was an extremely difficult technical achievement. HC-800LL is the latest model in the lineup and is designed to help resolve a variety of issues faced by the food processing industry today, including increasing amounts of print content per label and the reduced space available for applying labels due to packaged portions becoming smaller.

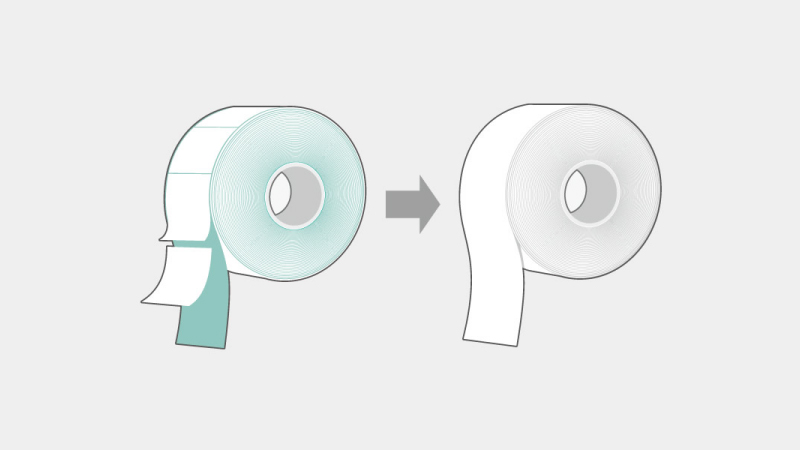

Label rolls replaced half as often and inventory space requirements cut in half

Since linerless labels do not have paper liners, there are twice as many labels per roll for the same roll diameter compared to regular labels. That means that during operation, the linerless label rolls need to be changed half as often, and the inventory space required for linerless labels is also halved. And of course, there is no waste arising from having to dispose of liner paper.

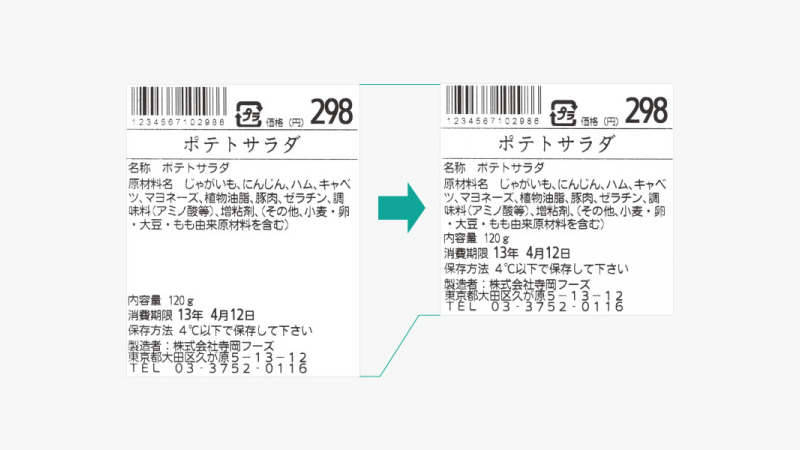

Labels are automatically cut according to the amount of print content

HC-800LL automatically cuts the label according to the amount of print content each time a label is printed. With regular labels, the label size is determined by the maximum print content size, so when there is a small amount of content a large part of the label is empty. HC-800LL adjusts the label size according to the amount of print content, so labels are printed without wasting label material. In addition, the cutter is built to be extremely durable.

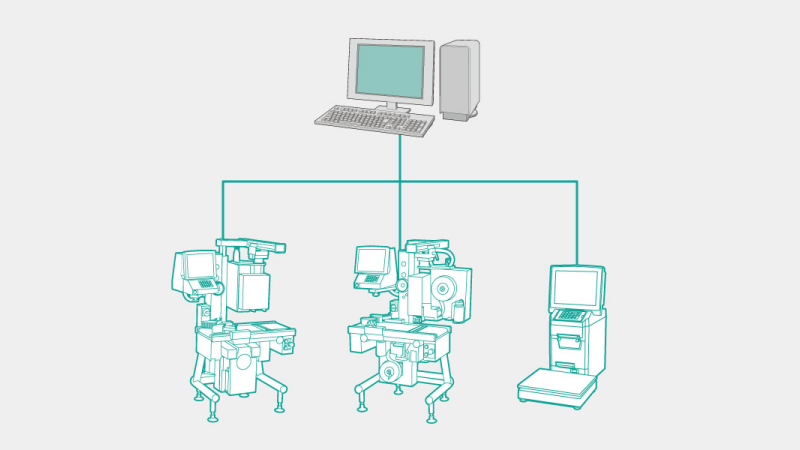

Network connectivity for centralized data management

Connecting the labeler to a your LAN using the PCS-L700 labeler controller allows you to:

- Centrally manage label masters

- Manage printing dates

- Manage printing orders

- Monitor labeling progress

- Centrally manage printing history

Specifications

Dimensions

| Package size | Width: 50 to 240 mm | ||

|---|---|---|---|

| Length: 70 to 350 mm | |||

| Height: 15 to 190 mm | |||

| Label size | Upper Applicator Standard cylinder |

Width: 59 mm | |

| Length: 35 to 130 mm | |||

| Bottom Applicator | Width: 59 mm | ||

| Length: 35 to 130 mm | |||

| Power consumption | 330 W (for cassette type UB) | ||

| Dimensions of main unit | W 750 x L 714 x H 1,410 mm | ||

| Conveyor Height | 800 ± 50 mm | ||

| Power supply | 100V Single phase | ||

| Air consumption | Upper Applicator: Max. 1.3 ℓ/seet Bottom Applicator: Max. 1.1 ℓ/seet |

||

Variations

Variations of upper and bottom applicator labels

| Model | HC-800LL UB | HC-800LL U+B | HC-800U + LLB | HC-800LL U | HC-800LL B |

|---|---|---|---|---|---|

|

|

|

|

|

|

| Upper Applicator | Linerless labels | Linerless labels | Standard labels | Linerless labels | ― |

| Bottom Applicator | Linerless labels | Standard labels | Linerless labels | ― | Linerless labels |