MAP/skin packaging machine with integrated

automatic weigh-labeler

PW-5600LL

Food IndustryMain Features

PW-5600LL is versatile and efficient MAP/skin packaging machine with an integrated automatic weigh labeler offering 3 different sealing modes - MAP (Modified Atmosphere Packing), VSP (Vacuum Skin Packing) and Seal Only (Natural gas).

Pack, weigh and label with only one operator

Fulfilling the needs for seafood and meat packaging in supermarkets, processing centers and food factories.

One operator can pack, weigh, and label all in one efficient process.

High quality Modified Atmosphere Packing (MAP)

- MAP packing improves shelf-life (around 2 weeks)

- Gas replacement rate ≥99%

- Maintains the natural color of the food

- Refilling O2 makes red meat look fresher for longer

- Up to 12 packs/minute including weighing and labeling

Hygienic Vacuum Skin Packing (VSP)

- VSP packing can make greatly increase shelf-life (normally more than a month)

- Isolate natural gas and avoid the reproduction and growth of bacteria

- Maintain the quality and shape of the product for greater shelf appeal

- Up to 12 packs/minute including weighing and labeling

Fast top sealing

The PW-5600LL also provides a fast and hygienic top sealing only option, with speeds of up to 20 packs/minute including weighing and DIGI linerless labeling.

Compact footprint

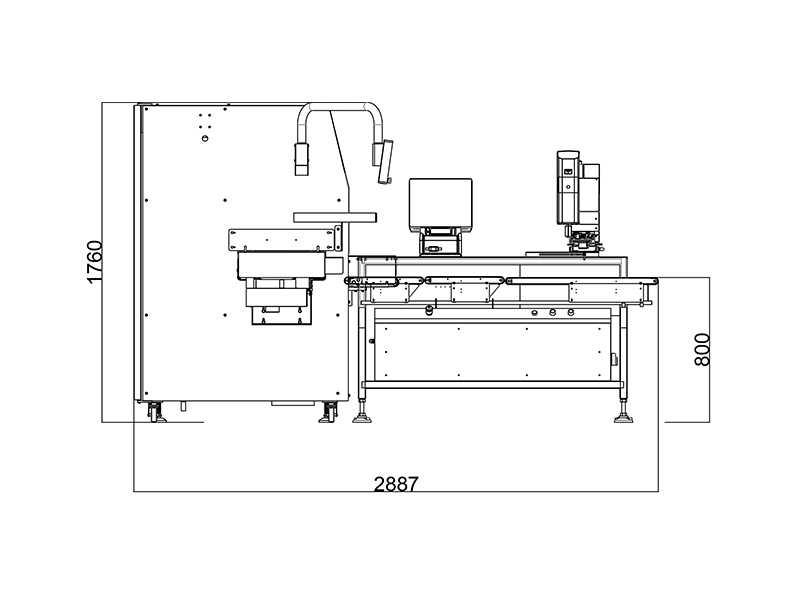

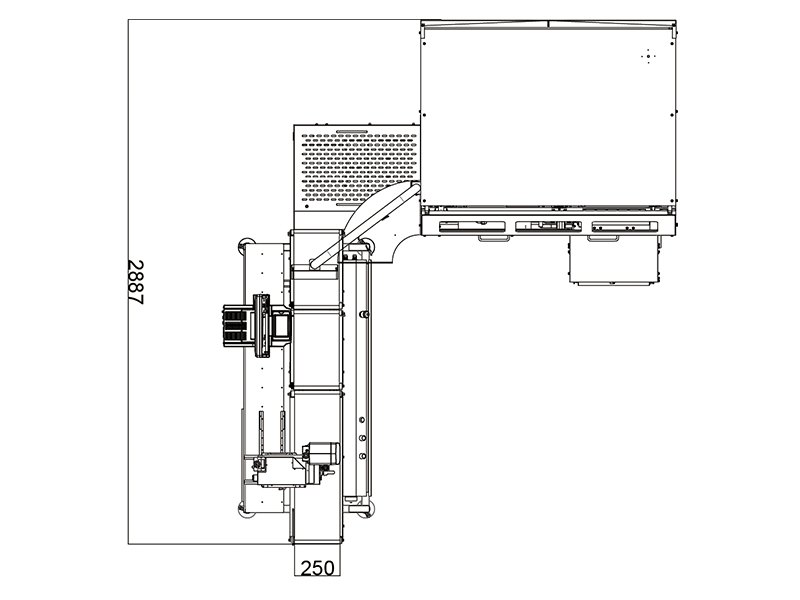

The compact footprint offers flexibility and maximum space efficiency especially for supermarket backroom production.

Simple and labor-saving mold changing

Supporting 3 sets of molds for different products, the automatic lifting shelf makes switching molds quick and easy as it stops at the accurate position every time. Reheating only requires 10 minutes after switching.

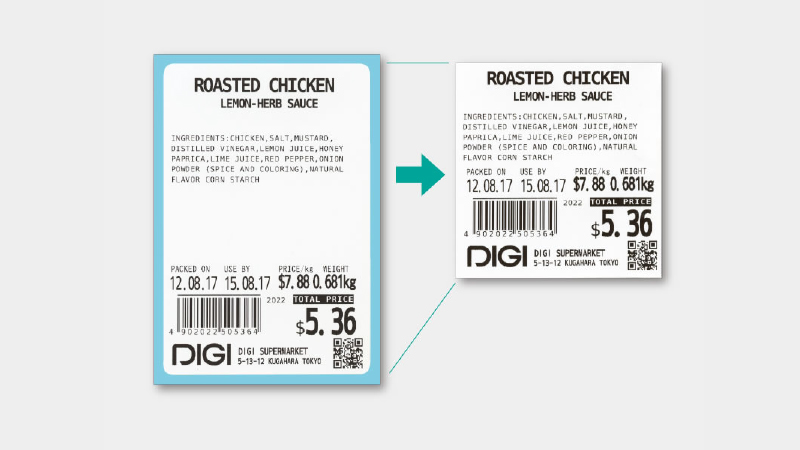

Variable length label printing using auto-sizing and auto-cutting

The auto-label-sizing feature eliminates unused space on the label and automatically adjusts the label size. This reduces the label cost and makes labels more attractive. Linerless labels automatically adjust the label size to the content, using a continuous roll of adhesive label material. This means you can print a different-sized label for each product, and longer labels are simple to print.

Specifications

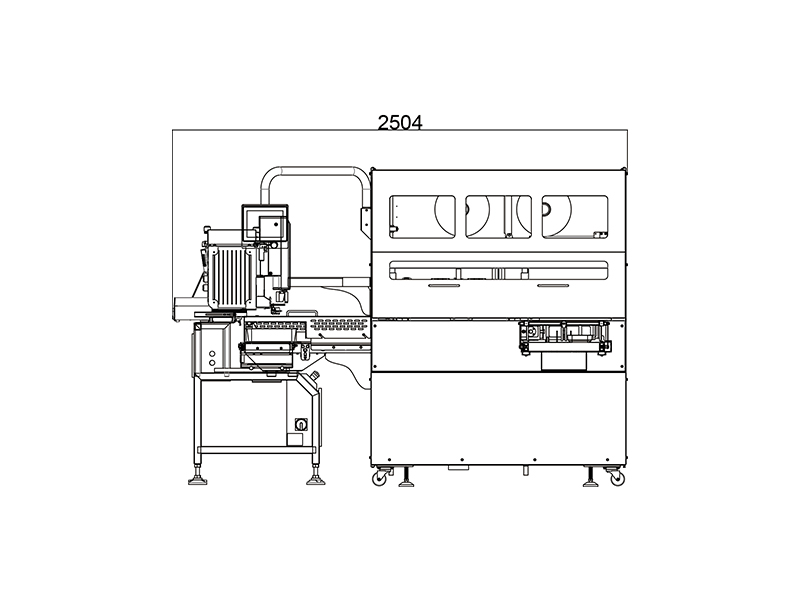

Dimensions

Packing

| Packaging option | MAP, VSP, Sealing |

|---|---|

| Function | Front infeed, left or right outfeed |

| Vacuum pump | 100m3/h, Oxygen pump |

| Compressor | External |

| Power supply | 380V/200V 3 phase |

| Power consumption | 8kW |

| Gas consumption | 0.5m³/min |

| Air consumption | 1m³/min |

| Gas tank volume | 0.185m³ |

| Gas flush option | 3 (N2, CO2, O2) |

| Film width | 305mm |

| Molds size (LxW) and arrangement | 15 cm x 23 cm: 2*1=2 18 cm x 25 cm: 2*1=2 21 cmx 30 cm: 1*1=1 |

| Molds changeover | Semi-automatic |

| Tray materials | PSE, PP |

| Film | Unprinted film, Printed film |

| Diameter of film roll | max. 300mm |

| Machine weight (kg) | 1100kg |

| Machine size (L mm x W mm x H mm) | 1960 x 2217 x 1742 |

| Cycles / min MAP | 5~6 |

| Cycles / min SKIN | 5~6 |

| Cycles / min SEAL ONLY | 10 |

Weighing & Labeling

| Label type | Linerless | ||

|---|---|---|---|

| Label size | Automatic application | Width | 44-78mm / 1.73-3.07inches |

| Length | 28-105mm / 1.10-4.13inches | ||

| Manual application | Width | 44-78mm / 1.73-3.07inches | |

| Length | 20-500mm / 0.79-19.69inches* *max. length 300mm / 11.8inches |

||

| Labeling angle | 0 or 90 or 180 or 270 degrees | ||

| Dot density | 12dot / mm (300dpi) | ||

| Font | True type font | ||

| Speed | Max. 35 packages / min | ||

| Display panel | TFT LCD color 15" touch panel | ||

| Memory for programmable files | 32GB | ||

| Weighing | Range 0~3000g | ||

| Interval | 1g | ||

| Conveyor height | 800mm±50mm | ||

| Outfeed conveyor length | 800mm | ||

| Weighing conveyor length | 400mm | ||

| Belt width | 250mm | ||

| Power consumption | 660W | ||

| Power supply | AC220V/110V 50/60Hz | ||