This automatic in-motion dimensioning and weighing system offers speedy measurement of package dimensions and weight on a conveyor. The first in the industry to enable measurement down to 5 mm in thickness.

SMART QBING

LogisticsMain Features

SMART QBING is a system designed for logistics centers that fully automates dimensioning and weighing of packages. Get quick and accurate measurements by simply passing the items along on the conveyor. As an industry first, SMART QBING can measure items that are as little as 5 mm thick. In today's busy logistics workplace, pressured by the rapid rise in delivery service use coupled with a troubling increase in re-deliveries due to customer absence, speedy and accurate measurement of package dimensions can dramatically assist in streamlining operations and reducing costs.

Non-stop speedy dimmension and weight measurement

Three built-in scales under the conveyor do the weight measurement. Using a patented weighing algorithm, packages with as little as 40 cm spacing on the conveyor can be accurately weighed one after another at high speed without missing a single item. Combining the 40 cm spacing with SMART QBING's impressive 120 m/minute conveyor speed, you can process up to 9000 cases/hour for an average item length of 40 cm. DIGI has achieved this level of performance because we are a weigh scale manufacturer, and high-speed processing is our strong point.

A first for the logistics industry! Measuring packages with 5 mm thickness!

SMART QBING has a high-precision infrared transmission sensor built into its gate sensor, allowing three-dimensional measurements with 5 mm pitch. By adding our Thin Item Detection option, the system can automatically dimension items of as little as 5 mm thick. Conventional systems have only been able to handle items of at least 3 cm thickness. So, being able to automatically measure 5 mm-thick items is truly a first for the industry.

Integrated bar-code scanning

Barcodes are indispensable to logistics operations and SMART QBING has built-in barcode scanning functionality. You can select optional equipment that ranges from manual hand scanners all the way up to high performance automatic scanning directly from the conveyor.

The barcode, dimensions, and weight data are grouped and sent to a host, such as a PC or PLC, making it simple and easy to integrate SMART QBING with warehouse management systems, sorting lines, and shipping operations systems. This, in turn, contributes to logistics cost reductions, lower storage costs, and more effective utilization of warehouse space.

A variety of models to suit the size and application

Choose from three model series with different conveyor sizes according to your item size and installation space requirements: the 60 cm-wide SQ-2000 series, the 90 cm-wide SQ-3000, or the 122 cm-wide SQ-4000 series.

These systems can be flexibly configured to provide dimensions-only, weight-only, or barcode-and-weight-only measurements.

Specifications

Dimensions

SMART QBING specification

|

SQ-2002

SQ-2003 |

SQ-2202

SQ-2203 |

SQ-2200

|

SQ-3002

SQ-3003 |

SQ-3302

SQ-3303 |

SQ-3300

|

SQ-4302

|

|

|---|---|---|---|---|---|---|---|

|

Conveyor width

|

600mm | 900mm | 1220mm | ||||

|

Function

|

Weighing | Measurement・ Weighing |

Measurement | Weighing | Measurement・ Weighing |

Measurement | Measurement・Weighing |

|

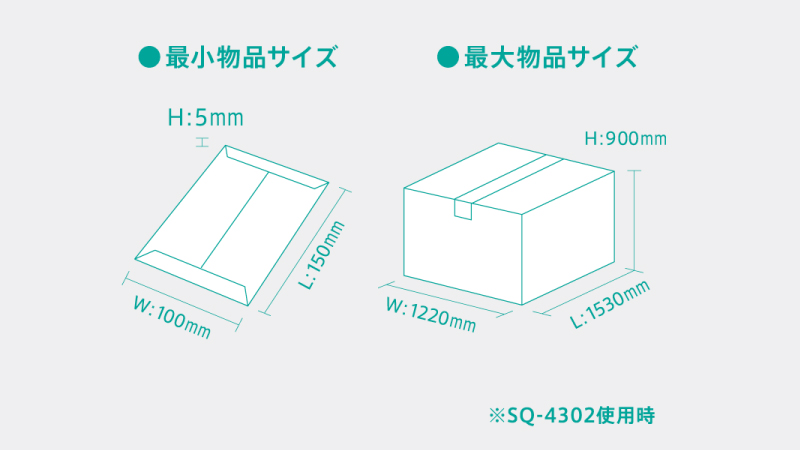

Minimum package size(mm)

|

150(L)× 100(W)× 30(H) (*) When using thin item detection option, it becomes 5mm (H). |

||||||

|

Maximum package size

|

1530(L)× 600(W)× 600(H) | 1530(L)× 900(W)× 900(H) | 1530(L)× 1220(W)× 900(H) | ||||

|

Dimension scale

|

N/A | 5mm | N/A | 5mm | |||

|

Size detection

|

N/A | Infrared transmission sensor | N/A | Infrared transmission sensor | |||

|

Weighing capacity

|

50kg | N/A | 50kg | N/A | 50kg | ||

|

Weighing

|

50g (0~5kg)/ 100g (Over 5kg~50kg) |

N/A | 50g (0~5kg)/ 100g (Over 5kg~50kg) |

N/A | 50g (0~5kg)/ 100g (Over 5kg~50kg) | ||

|

Weighing range

|

200g~50kg | ||||||

|

Weight sensor

|

Loadcell | N/A | Loadcell | N/A | Loadcell | ||

|

Weighing units

|

2 groups (SQ-2002/SQ-2202) 3 groups (SQ-2003/SQ-2203) |

N/A | 2 groups (SQ-3002/SQ-3302) 3 groups (SQ-3003/SQ-3303) |

N/A | 2 groups | ||

|

Conveyor speed

|

30~120m/min (variable) | ||||||

|

Minimum article conveyance interval

|

700mm (SQ-2002/SQ-2202) 400mm (SQ-2003/SQ-2203) |

400mm | 700mm (SQ-3002/SQ-3302) 400mm (SQ-3003/SQ-3303) |

400mm | 700mm | ||

|

Interfaces

|

RS-232, RS-422, Ethernet (100BASE-TX), DIO (External control signal input / output), USB (Data storage only) | ||||||

|

Power supply

|

AC200V, 3-phase, 50/60Hz | ||||||

|

Power consumption

|

1.1kVA | ||||||

|

Operating temperature/ Humidity

|

-10 ~ +40℃/ 15 ~ 85%RH (no condensation) | ||||||

|

Dimensions (mm)

|

1735(L)× 1050(W)× 566(H) | 1735(L)× 1030(W)× 1240(H) | 1735(L)× 1350(W)× 566(H) | 1735(L)× 1350(W)× 1560(H) | 1735(L)× 1670(W)× 1560(H) | ||

|

Net weight

|

400kg (SQ-2002) 405kg (SQ-2003) |

410kg (SQ-2202) 415kg (SQ-2203) |

390kg | 440kg (SQ-3002) 445kg (SQ-3003) |

460kg (SQ-3302) 465kg (SQ-3303) |

450kg | 500kg |

Variations

Automatic Weigh Scale (Weight Only)

|

SQ-2002

SQ-2003 |

Automatic scale that measures weight. Weighs packages up to 153 cm (L) x 60 cm (W) x 60 cm (H) and 50 kg weight, in 100 g increments (50 g increments for items up to 5 kg). SQ-2003 is a high-speed processing model, with a min. conveyor item spacing of 40 cm. (SQ-2002 supports a min. 70 cm item spacing.) |

|

SQ-3002

SQ-3003 |

Automatic scale that measures weight. Weighs packages up to 153 cm (L) x 90 cm (W) x 90 cm (H) and 50 kg weight, in 100 g increments (50 g increments for items up to 5 kg). SQ-3003 is a high-speed processing model, with a min. conveyor item spacing of 40 cm. (SQ-3002 supports a min. 70 cm item spacing.) |

Automatic Dimmensioning Weigh Scale (Dimensions and Weight)

|

SQ-2202

SQ-2203 |

Automatic scale that measures dimensions and weight. Measures and weighs packages up to 153 cm (L) x 60 cm (W) x 60 cm (H) and 50 kg weight. Dimensions are measured in 5 mm increments; weight is measured in 100 g increments (50 g increments for items up to 5 kg). SQ-2203 is a high-speed processing model, with a min. conveyor item spacing of 40 cm. (SQ-2202 supports a min. 70 cm item spacing.) |

|

SQ-3302

SQ-3303 |

Automatic scale that measures dimensions and weight. Measures and weighs packages up to 153 cm (L) x 90 cm (W) x 90 cm (H) and 50 kg weight. Dimensions are measured in 5 mm increments; weight is measured in 100 g increments (50 g increments for items up to 5 kg). SQ-3303 is a high-speed processing model, with a min. conveyor item spacing of 40 cm. (SQ-3302 supports a min. 70 cm item spacing.) |

|

SQ-4302

|

Automatic scale that measures dimensions and weight. Measures and weighs packages up to 153 cm (L) x 122 cm (W) x 90 cm (H) and 50 kg weight. Dimensions are measured in 5 mm increments; weight is measured in 100 g increments (50 g increments for items up to 5 kg). |

Automatic Dimmensioning Scale (Dimensions Only)

|

SQ-2200

|

Automatic scale that measures dimensions. Measures packages up to 153 cm (L) x 60 cm (W) x 60 cm (H) in 5 mm increments. |

|

SQ-3300

|

Automatic scale that measures dimensions. Measures packages up to 153 cm (L) x 90 cm (W) x 60 cm (H) in 5 mm increments. |

Case Studies

SMART QBING streamlines shipping operations, reducing the burden on staff and realizing a variety of operational improvements

Yamada Bee Company, Inc.

Yamada Bee Company develops, manufactures, and sells honey, royal jelly, and other bee products, as well as natural foods, health foods, and cosmetics. It is remaining true to its goal of contributing to harmony between nature and society by taking responsibility for the entire beekeeping process, from production to shipping. The company recently introduced SMART QBING Automatic Dimensioning Weigh Scale to improve efficiency and reduce personnel requirements in its shipping operations.FAQ

-

What sort of applications is SMART QBING used for?SMART QBING is mainly used in logistics operations to measure the weight and external dimensions of shipping packages. Since the volume of the package can be easily calculated from the dimensions, you can use SMART QBING to increase the efficiency of your warehouse and shipping management process.

-

How large a package can be measured?The maximum package size is 153 cm (L) x 122 cm (W) x 90 cm (H), weighing up to 50 kg.

The minimum size is 15 cm (L) x 10 cm (W) x 0.5 cm (*), weighing 200 g.

(*) When using the Thin Item Detection option -

Can you measure items that are not in the shape of a box (cube)?SMART QBING can measure the maximum size of an item in each of the three dimensions. But, depending on the shape, some items cannot be correctly measured. Please contact your local dealer for details.

-

How is an item measured when it is placed diagonally on the conveyor?SMART QBING has a function that allows it to correctly measure an item even if it is placed diagonally on the conveyor.

-

Can a barcode be read during a measurement?A barcode can be scanned and added to the dimension and weight data of the item.

A variety of barcode scanners are available to meet customer requirements. -

What types of barcodes can be read?SMART QBING supports most barcodes commonly used in the logistics industry: NW-7 (Codabar), Code 39, Code 128, and JAN, as well as two dimensional (2D) bar codes. Please contact your local dealer for details.

-

Is possible to send the measurement data to a PC?SMART QBING is equipped with an Ethernet interface and an RS-232 interface for connecting to and sending the measurement data to a PC. You can also plug a USB flash drive into SMART QBING USB port to save the measurement data and then move it to a PC.