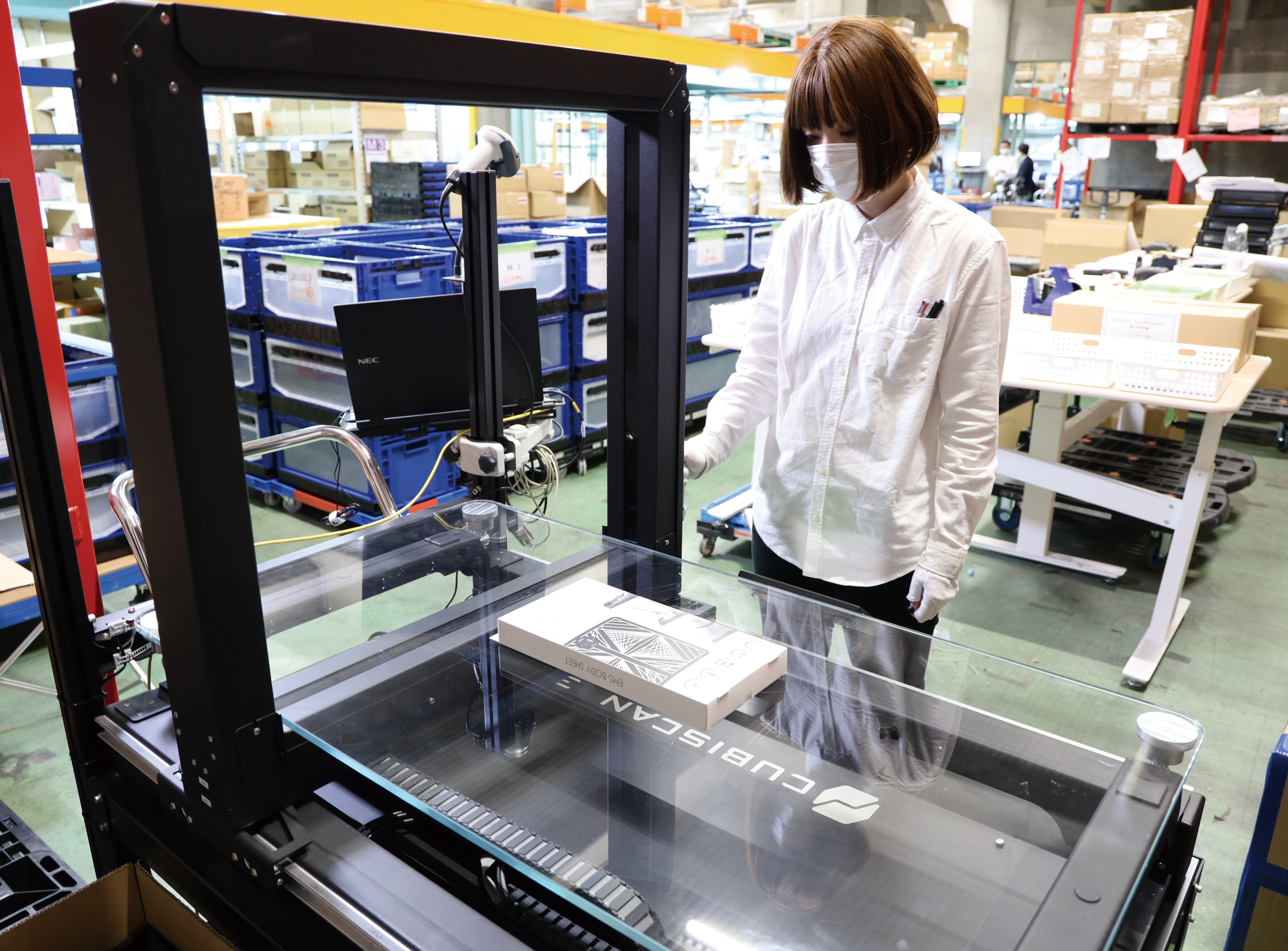

AI Picking Cart with Built-in Weigh Scale and SPK High-precision Dimensioning Weigh Scale

Keihin Distribution Co., Ltd.

LogisticsAI Picking Cart with Built-in Weigh Scale and SPK High-precision Dimensioning Scale improve productivity by increasing picking accuracy through double inspection (scanning and weighing) and by reducing post-picking inspection work when packaging

Keihin Distribution Co., Ltd. has been involved in logistics operations for over 40 years, handling mostly small-quantity, high-variety products. The company was initially involved primarily in distribution center operations and home delivery services for major department stores, and now focuses on offering logistics services to mail-order companies and retailers. To improve the accuracy of shipments for their customers selling cosmetics and general merchandise they introduced picking carts with built-in weigh scales (AI Picking Carts) and dimensioning weigh scales (SPK).

The Challenge

Increase accuracy of product inspection during picking, improve packaging productivity, and reduce the space required for packaging.

Our Solution

AI Picking Cart with Built-in Weigh Scale and SPK High-precision Dimensioning Weigh Scale

Benefits

Using SPK for capturing product weight and dimensions to create a product master, and then importing the data into AI Picking Carts, picking and inspection have been combined into one operation. This eliminated the need for post-picking inspection, and has reduced the space required for packaging products.

Customer Profile

| Company: | Keihin Distribution Co., Ltd. |

|---|---|

| Country: | Japan (Yokohama) |

| Web: | https://www.keihin-haiso.co.jp/index.html |