Main Features

A new concept in banding machines that showcases the product while still offering information and secure packaging.

Product strap banding label with printing on demand for a new solution

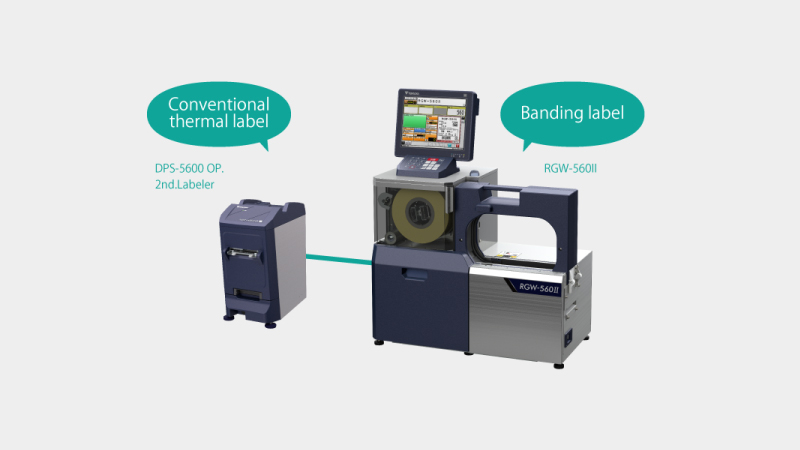

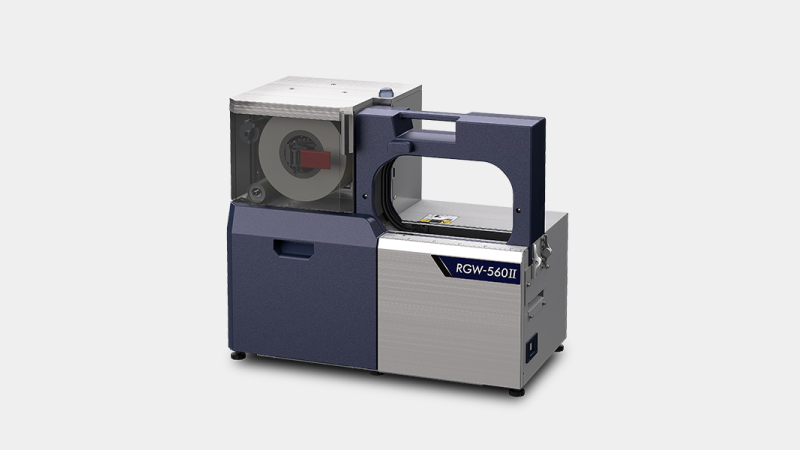

DIGI's unique solution, RGW-560II showcases the product by sophisticated graphic design banding labels. It provides printing on demand with flexible images and information pre-programmed in the machine.

Adding value to customers’ products with a sleek, flexible, graphic banding label

The RGW-560II is a new concept in banding machines that showcases the product while still offering information and secure packaging. The flexible product strap eliminates the need for distracting labels allowing for a better package design appealing to customers.

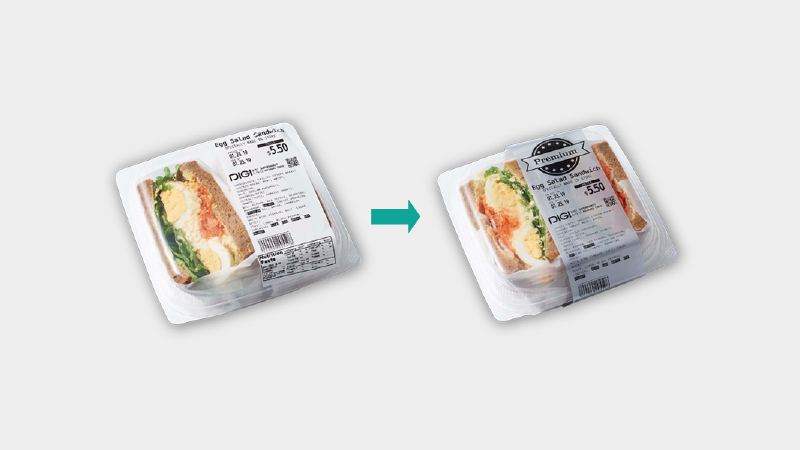

Impact product presentation

Normal white labels increasingly obstruct the product view and degrade the appearance. The banding label’s sophisticated graphic design printing allows customers a better impression of the product.

Flexible design printing

The RGW-560II enables to the flexible design to print on demand by thermal transfer. The banding label has space to fit a wide variety of advertising images or multiple lines of information.

Secure packaging

The banding label uses a heat seal to safely secure the package, avoiding any chance the lid would open unexpectedly. No need to tape manually.

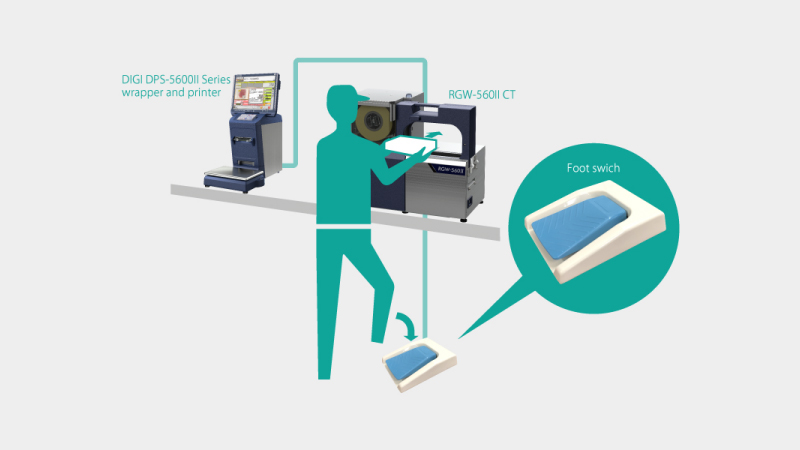

Utilize DIGI’s 5600 series console

The RGW-560II uses the DIGI 5600 series console to enable communication with other backroom wrapping machines or printers. Easy and familiar operation helps improve efficiency.

Consumables

The RGW-560II uses OPP film, ink-ribbon, and additional labels as consumables, which are easily sourced locally. Additional labels are only used for the transparent banding label so the barcode can be scanned properly.

Specifications

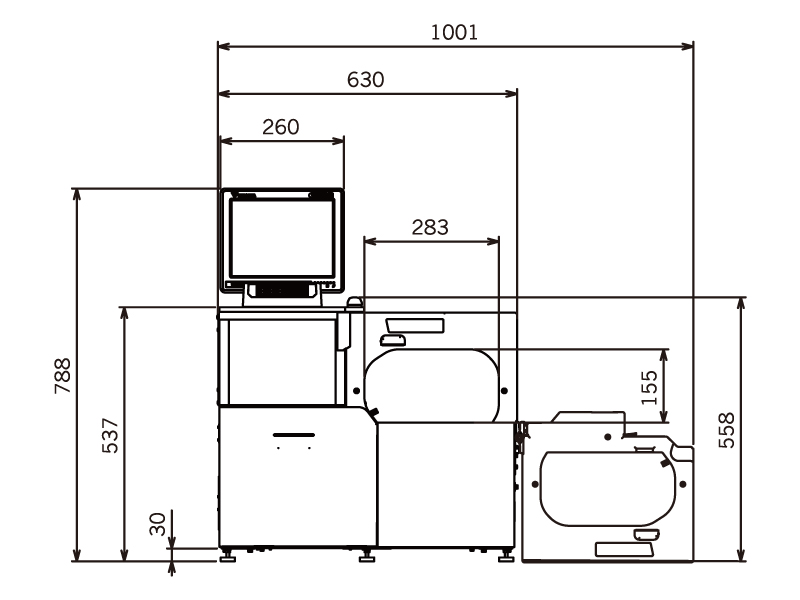

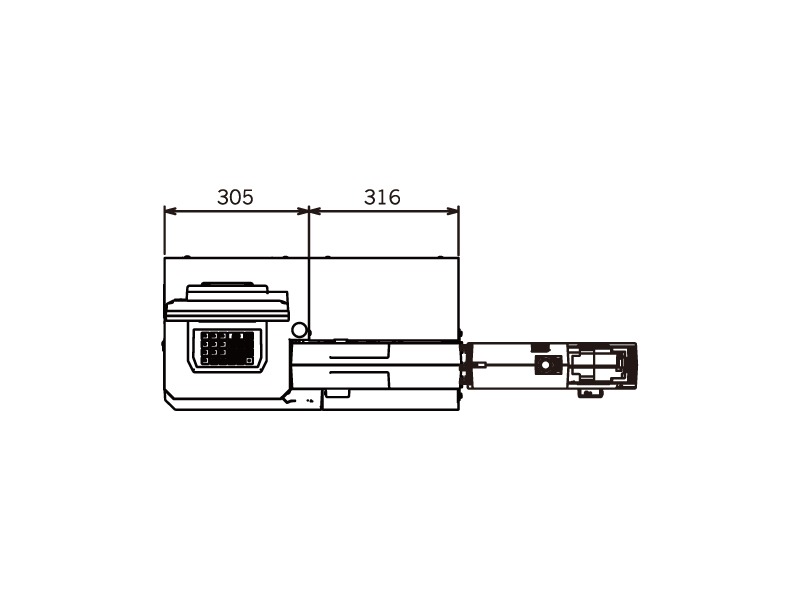

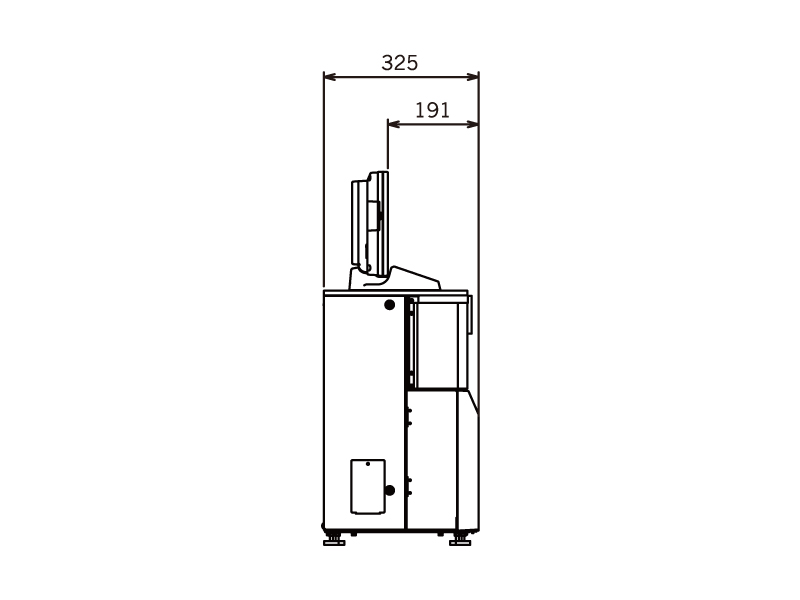

Dimensions

Banding

| Package size | Width: 50-240mm (2.0-9.4 inches) Height: 10-150mm (0.4-5.9 inches) Depth: 80mm or more (3.1 inches or more) |

|---|---|

| Banding speed | Max: 12 packages/min. Note: The banding speed may vary depending on the length of the band format. |

Printer

| Banding film type | OPP |

|---|---|

| Print method | Thermal transfer |

| Dot density | 11.8dot/mm (300dpi) |

| Film width | 60mm or 40mm |

| Printing area | Max. 300mm (Between 95mm to 395mm from top of banding label) |

Operation console

| Display panel | TFT LCD color (10.4 inches) touch panel |

|---|---|

| Operation keys | Mechanical keys and touch panel |

| Memory for programmable files | 18GB |

General

| Power source and power consumption |

AC 100-120 or 220-240V, 50/60Hz 280W |

|---|---|

| Net weight | ・Apporpx. 41.4kg (RGW-560Ⅱ) ・Apporpx. 38kg (RGW-560ⅡCT) |

| Operation humidity | 40 to 80%RH with no condensation |

Variations

RGW-560II CT

Case Studies

Case Study

Globus utilizes portable RGW-560IIS for efficient strap-banding across departments.

Globus-Markt in Krefeld

The Globus store in Krefeld sought a flexible and transportable Product Strap Banding solution and increased product presentation across in-house production departments such as the Sushi bar.Allseas Sushi relies on RGW-5600II to simplify their daily operation

Allseas Sushi

Allseas Fisheries Corp., operator of Allseas Sushi, is one of Canada’s largest seafood distribution companies. Allseas Sushi is utilizing DIGI’s RGW-560II product strap banding machine for clear and attractive labeling of their sushi products.FAQ

-

Do you provide a solution for larger trays which do not fit?The manual mode option is provided for larger trays.