LIS-CS series

Expert automatic production line package inspection using a high-precision camera/scanner combination.

A variety of inspection/verification checks allows fully automatic detection of labeling defects to substantially save on labor in the label inspection process.

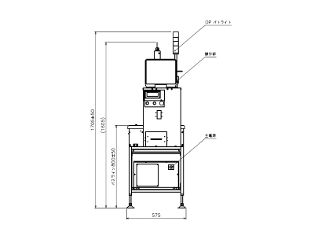

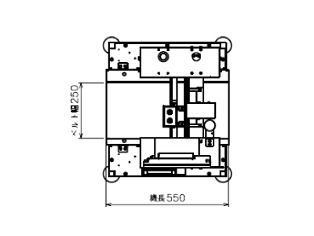

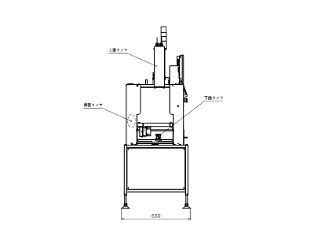

Dimensions

Common specification

| Power-supply voltage | AC100V 50/60Hz |

|---|---|

| Maximum number inspection history saved | 4000 cases *1 |

| Number of items that can be registered | 999 variety |

| Maximum inspection capacity | 72 pieces/min. |

*1: One item for each item number change

General purpose model

|

LIS-CS USBC

|

LIS-CS UCBS

|

||

|---|---|---|---|

| Intended use | For tray packs, general food packs | ||

| Device | Upper side: Scanner Lower side: Camera |

Upper side: Camera Lower side: Scanner |

|

| Dimensions of main unit | Conveyor length | 550 mm | |

| Depth | 550 mm | ||

| Height | 1410 to 1560 mm | ||

| Belt width | 230mm | ||

| Path line | 750 mm to 850 mm | ||

| Power consumption | 56 W (Max) *2 | ||

| Integrated air sorting | × | ||

Specific use model

|

LIS-CS1

|

LIS-CS PLW

|

LIS-CS SND

|

||

|---|---|---|---|---|

| Intended use | For triangular rice ball inspection only | For Reverse pillow packaging rice ball inspection only | For sandwich inspection only | |

| Device | Horizontal side: Camera Horizontal side: Scanner |

Upper side: Scanner Lower side: Camera |

Upper side: Camera Lower side: Scanner |

|

| Dimensions of main unit | Conveyor length | 500 mm | 539 mm | 550 mm |

| Depth | 550 mm | 665 mm | ||

| Height | 1180 to 1330 mm | 1278 to 1378 mm | 1410 to 1560 mm | |

| Belt width | 45 mm | 73.5 mm | 230 mm | |

| Path line | 700 to 850 mm | 750 to 850 mm | ||

| Power consumption | 27 W *2 | 30 W *2 | 50 W (Max) *2 | |

| Integrated air sorting | ◯ | |||

** When considering, please check with the sales representative beforehand if the target product can be inspected with this product.