Simultaneous contaminant detection and quality checking

Xray Inspection System

IndustrieBelangrijkste kenmerken

Anritsu X-Ray Inspection Systems give food and pharmaceutical producers the best combination of contaminant detection, reliability, and low total cost of ownership. Anritsu has the advanced technology you can trust to protect your customers from even the smallest contaminants.

With outstanding accuracy and precision, our x-ray machines can detect metal, stone, bone, glass, and more, using our advanced HD and UltraHD technology. Beyond detection, Anritsu X-Ray Inspection provides missing product, shape detection, virtual weight, count, and package check.

Anritsu UltraHD Technology is known for its ability to detect contaminants of only 0.2 mm diameter, including ferrous, non-ferrous, and stainless contaminants.

Anritsu HD Systems can detect metal contaminants as small as 0.4mm, and glass and stones at 1.0mm to 2.0 mm.

Best in class inspection capability - 0.2mm diameter metal

The Anritsu UltraHD technology installed in our machines can detect even the most minute contaminants - 0.2 mm diameter ferrous, non-ferrous and stainless steel spheres at production line speeds. Tuning the algorithm to match the new high-sensitivity sensor easily detects low-contrast contaminants such as bone and plastics.

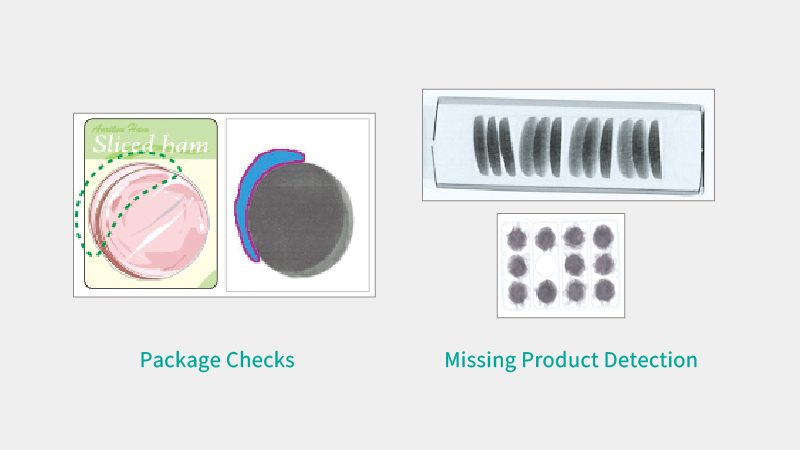

Package Checks

Packages of sliced ham, etc., are checked to ensure none of the contents is caught in sealed parts.

Missing Product Detection

[Count detection] Inspects the number of pieces per pack of vertically packed biscuits or cookies.

[Virtual weight detection] Shortages in the number of items in a package can be found when the amount is displayed as number of contained pieces and detecting such shortages based on mass is difficult, because each piece has variable mass.

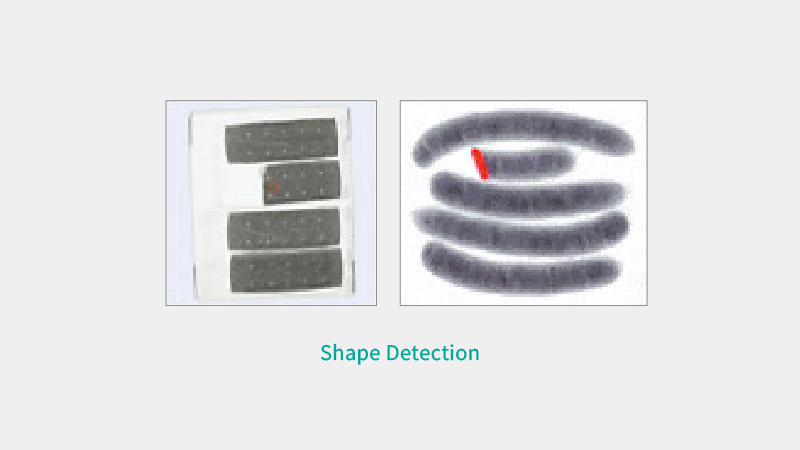

Shape Detection

The shape, area and mass are analyzed from x-ray images to find irregularities including breaks and chips. Missing fillings can also be spotted.

Easy Operation

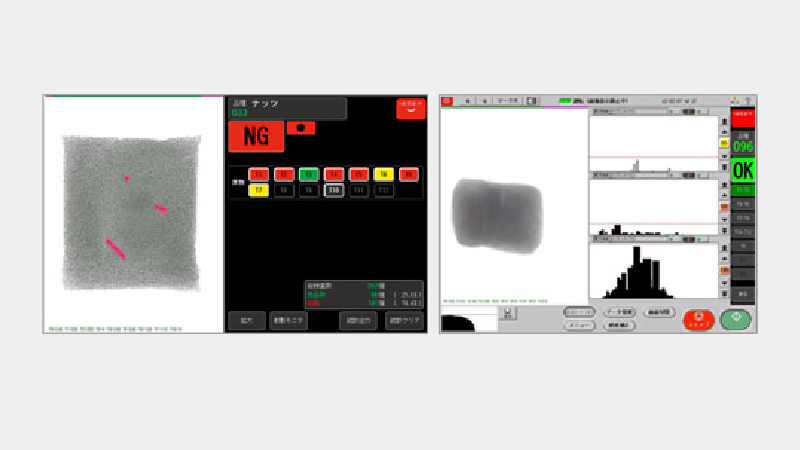

Projection monitor

The x-ray image is displayed graphically in an easy to read display. Detection limits are easily adjusted to enhance detection sensitivity and reduce false rejections.

Software features

Simultaneous inspection for all types and sizes of contaminants including wire, glass, stone and bone.

Optimized settings per application, 70+ unique algorithms.

Dynamic filters greatly enhance detection with reduction of possible false rejects.

Full auto-learn process - all x-ray settings are learned at the touch of a button.

Password protected - once set the system can be locked out from changes by production staff.

Allows multiple reject criteria including contaminant, virtual weight, count, missing and more.

Full reject log and image capture capability with time/day stamps for all rejected products.

Built-in multi-lane system capability - 1 to 5 lanes.

Stable, repeatable performance

Full auditing capability through Anritsu's Operation Check for HACCP compliance

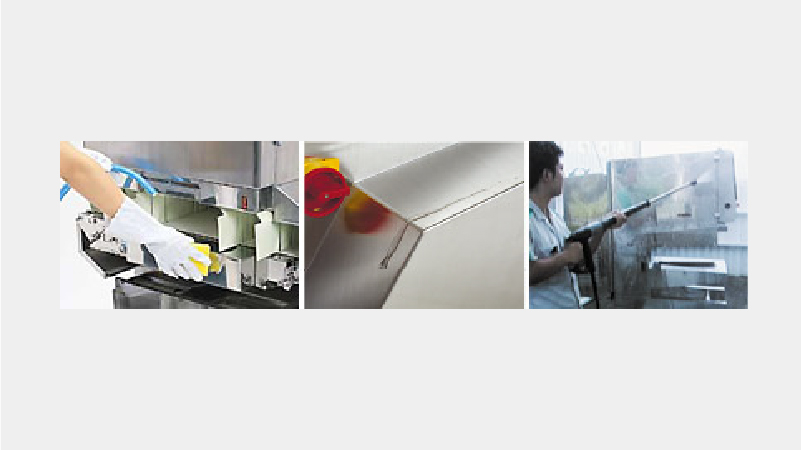

Tool free belt removal

No tools are required for removing/attaching the conveyor belts and rollers including the front cover and x-ray leakage prevention curtain.

Easy-to-clean design

Anritsu x-ray inspection systems are certified to IP66 dust-proof/waterproof. The system's angled surfaces prevent water from accumulating after system cleaning. The sanitary design line-up with IP69K option is also available.

Simple information management

X-ray images and inspection logs can be saved to the USB memory for HACCP compliance. All Anritsu systems can be connected, via Ethernet, to QUICCA. QUICCA provides line status information, centralized reporting and data storage.

Specificaties

Afmetingen

| SERIES | FEATURES | MAIN FUNCTION | MAIN SPEC | |

|---|---|---|---|---|

|

Long life model[XR75 series] | Advanced Long Life Technology provides reliable and accurate inspection with reduced power consumption. | Contaminant Detection Package Check / Void Check / Missing Product Detection / Shape Detection / Mask Functions |

- |

|

DualX [Dual Energy] | Analyzing two different x-ray energy signals, it clearly distinguishes contaminants from products. | Contaminant Detection Package Check / Void Check / Missing Product Detection / Shape Detection / Mask Functions |

- |

|

DualX HR [Dual Energy] | Equipped with a new High Resolution Dual Energy Sensor for enhanced detection performance | Contaminant Detection Package Check / Void Check / Missing Product Detection / Shape Detection / Mask Functions |

Product size: Maximum width 370 mm, Maximum height 220 mm |

|

Large model [XR75 series] | For products in large cartons, cases and bags. | Contaminant Detection Package Check / Void Check / Missing Product Detection / Shape Detection / Mask Functions |

Product size: Maximum width 370 mm, Maximum height 220 mm |

|

Side View | For upright products | Contaminant Detection Mask Functions |

Product size: Maximum width 150 mm, maximum height 250 mm |

|

IP69K Sanitary Solution for Packaged Products | IP69K & Sanitary Design: The robust, open design allows accessible high-pressure, high-temperature cleaning and thorough drainage. | Contaminant Detection Package Check / Void Check / Missing Product Detection / Shape Detection / Mask Functions |

Detection area: Maximum width 370 mm, maximum height 200 mm |

|

Package Check | Specialized for package integrity checks | Package Check/ Count Detection | Detection area: Maximum width 240 mm, maximum height 120 mm |

|

For Pharmaceutical products (maximum height: 50 mm) | Suitable for pharmaceutical products that cannot be inspected by conventional means. | Package Check / Missing Product Detection / Shape Detection | Product size: Maximum width 205 mm, maximum height 50 mm |

FAQ

-

What is the role of Anritsu inspection systems?Delivering safety and security by quality inspection.

There is an increasing demand worldwide that food products should be processed and delivered to the consumers through safe and assured processes. In order to assure food product quality, a series of quality inspections must be performed in food manufacturing lines including the inspection of contaminants, product integrity, and the checkweighing of packaged items. The role of quality inspection systems are to ensure these inspections and to support the quality management.

Making invisible to visible—Anritsu quality inspection systems contribute to consumers' safety and fulfill a role appropriate to the needs of the times. -

Where are the inspection systems used?Anritsu inspection systems are mainly used in food and pharmaceutical factories.

Anritsu inspection systems are mainly used in food and pharmaceutical factories ranging from large mass production plants to small and medium size factories and family-run businesses with only a few production lines. Anritsu systems are installed for inspection or weighing processes in those lines. -

How do the inspection systems work?Anritsu's major products are X-ray inspection systems, metal detectors, and checkweighers. Their working principles are similar to household appliances but these industrial inspection systems have a distinctive feature: As installed in manufacturing lines, they perform inspections at production line speeds as high as hundreds of items per minute. Furthermore, the systems identify and reject defective items automtaically.

X-ray inspection system

Just like hospital X-rays and airport luggage X-ray machines do, X-ray inspection systems analyze an X-ray image that is obtained by radiating X-rays to an object. However, X-ray inspection systems differ from others in the following points:

Automatically performs in-line inspection and rejection at production line speeds

Inspection results vary depending on the object to be inspected and contaminants because X-ray absorption depends on the physical properties of the object and contaminants.