Packaging Solutions for Food Waste Reduction

Reducing Food Waste with MAP

Overview

Reducing Food Waste with Sustainable Packaging

Modified Atmosphere Packaging (MAP), which extends the shelf life of food is a key solution for reducing food waste.

As dual-income households increase and lifestyles become more diverse, bulk shopping and after-work grocery trips have become common. In this context, packaging that helps keep food fresh for longer is becoming increasingly important to consumers.

Customer Needs

Details

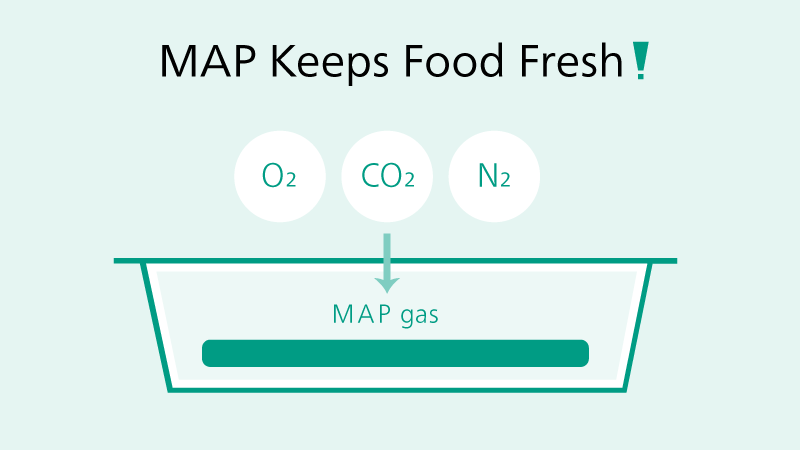

What is MAP Packaging?

MAP (Modified Atmosphere Packaging) is a packaging technology that replaces the air inside a food tray with gases such as oxygen, carbon dioxide, and nitrogen — in proportions suitable for food preservation.

This slows down oxidation and microbial growth, helping to maintain freshness for a longer time.

Keeping food fresh while reducing waste and unsold items — that is exactly what MAP makes possible.

Below are three key ways MAP contributes to reducing food waste.

Extended shelf life reduces disposal losses

MAP enables effective preservation of freshness, allowing products to have a longer shelf life compared to conventional packaging.

This helps reduce waste caused by expired products at the store level, while also lowering disposal costs.

In addition, a longer sales period allows for smoother inventory control and more flexible sales planning.

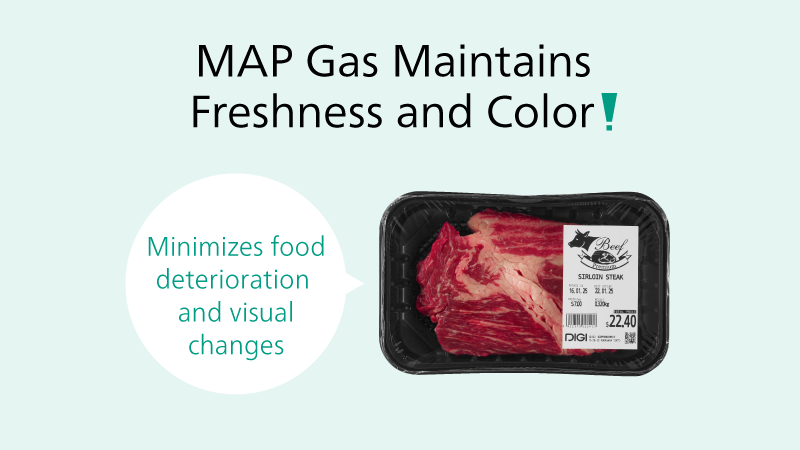

Fresh appearance prevents unsold products

MAP helps maintain the visual freshness of food, such as its color, for a longer period.

By keeping products visually appealing, it prevents loss of sales opportunities and reduces the number of unsold items.

Ultimately, this not only minimizes waste but also strengthens consumer trust in product quality.

Prevent deterioration losses during transportation and storage

Quality deterioration that occurs during long-distance transportation or storage can also be significantly reduced with MAP packaging.

Even during long-distance transport, the proper gas composition can help prevent food deterioration and discoloration.

As a result, the risk of disposal upon delivery to stores decreases, contributing to reduced losses in logistics and backroom operations.

Maintaining stable product quality throughout the supply chain also helps improve overall operational efficiency.