Using a structure that differed from existing balance-type scales that used a beam and weights, the Teraoka spring scale could measure the weight of an item by simply placing it on the platter of the scale.

History

The history of DIGI has been one of constantly creating new standards. From the very beginning when our company was established, we have continued to place the highest priority on creating products and services that provide maximum value to our customers.

At DIGI, we have always carefully considered the needs of our customers, providing precision and reliability, while pursuing increased efficiency. We are currently striving to provide ever-greater levels of both environmentally friendly and user-friendly benefits in our line of products.

| 1925 |  |

Toyoharu Teraoka, founder and first president, developed the Teraoka automatic spring scale.  |

|---|---|---|

| 1927 |  |

Asahi Koki Seisakusho K.K. established. |

| 1934 |  |

Takeharu Teraoka, the second president, established the Teraoka Research Center, the forerunner of Teraoka Seiko.  Start of mass production of the Teraoka spring scale for household use. The first product of its type in Japan, it utilized a bimetal temperature-error compensating device to correct erroneous readings caused by temperature changes, a problem found in conventional spring scales of the time.  |

| 1938 |  |

Company name changed from Teraoka Research Center to Teraoka Seikosho. |

| 1951 |  |

Japan’s first mechanical price-computing scale was released. This is the first scale in Japan to employ a disc chart that could be used to simultaneously read the weight and price of an item. It is also the first of its kind to use a temperature-insensitive spring.  |

| 1954 |  |

Japan’s first auto-winding camera, the AutoTera , was released. This camera could take seven successive pictures in three seconds, thanks to its built-in spring motor. At the time, it was unique in its ability to take continuous high-speed photographs. Its successor, the AutoTera II, could take up to twenty successive pictures at a time.  |

| 1960 |  |

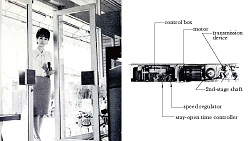

Fully electrically controlled automatic door engine was developed. At the time, automatic doors were large and expensive products that utilized air or oil pressure. A fully electric door engine meant that a cheap and compact automatic door product could be produced.  |

|---|---|---|

| 1962 |  |

The "Pearl" weighing scale received the first Good Design Award in the industry Ergonomically, the design included a dial that was set at eye level, and a weighing platter was positioned to make it easy to place items on it. The product was also praised for its visual design, which blended well into a store environment.  |

| 1965 |  |

The world’s first electronic price-computing scale was announced. This ground-breaking price-computing scale calculated the price of an item as soon as it was placed on the scale and then displayed the price digitally.  |

| 1970 |  |

The "Hanei" electronic price-computing scale was released. This is the company’s first commercialized electronic price-computing scale.  |

| 1971 |  |

Export of the "Hanei" electronic price-computing scale to France was started. A local type approval import license was received and sales were begun. This product was the first step in our overseas sales expansion. |

| 1973 |  |

The "DIGI" price-computing scale, which gave scales a new image, was released. This product was durable enough to maintain its precision over one million operations, and occupied only half the space of existing scales. It included a special temperature-compensation device and vibration prevention to reduce display flicker.  |

| 1976 |  |

The "DPS-8000" label printer was released. This is an electronic weighing and labeling machine developed by researching on-site operations in supermarket backrooms. It automatically printed a label for wrapped goods placed on the scale.  |

| 1978 |  |

The "DIGI Mark II", the first domestic load cell electronic price-computing scale was released. An electronic price-computing scale designed by examining the needs of the marketplace, this was a completely electronic scale that surpassed existing products in precision, durability, cost, and speed.  |

| 1979 |  |

The "SM-20" weighing POS system, combining an electronic price-computing scale and printer and enabling sales management, was released. This is a storefront management multi-function sales system that helps prevent stock shortages and dead stock. It can provide data such as total sales numbers and income for each item, as well as the number of customers per day.  |

| 1981 |  |

The "DPS-1000" scale printer with thermal printing and word-processing technology was released. This is the first scale printer in the world with a microcomputer-controlled thermal print head. As well as supporting barcode printing, it could store data, such as product names, unit prices, and taste-by-dates, and call them up when printing.  The "AWW-2000" automatic weigh-wrap-label system was released. This is the world’s first automatic wrapping and pricing machine that could automatically process weighing, packaging, and price labeling in one device. These functions had previously been handled by separate departments. This system established yet another new standard for supermarket backrooms.  |

|---|---|---|

| 1982 |  |

Scale label printers with thermal printing and word-processing technology were released. The "SM-40" scale label printer that could print the product name together with the price and weight on the label at sales counters was released. The "SM-50", which had a register function that printed receipts for multiple items, was released at the same time.  |

| 1984 |  |

The "SUPER-M3000" predictive POS register, which emphasized originality, was released. This product employed the first straight face-to-face counter approach in the industry. Its software programmed the following day’s store management from the sales results. This product marked the beginning of "POS Teraoka".  The "MATEX" automated warehouse control system was released. This is a count control system that not only streamlined warehouse entry and dispatch operations by introducing weighing machines into the counting operations, but also realized improvements in accuracy.  |

| 1987 |  |

Teraoka Weigh-System Pte. Ltd. in Singapore was established and local production was started. This was our first overseas production site. It played a role not only in development, but in marketing as well, and was the first step in our second wave of globalization.  |

| 1988 |  |

The "AW-2600Jr" automatic weigh-wrap-label system was released. This is an automatic weigh-wrap-label machine that realized a compact size and dramatically increased market penetration. Nicknamed "Wrappy", it set new standards in supermarket backrooms.  |

| 1989 |  |

DIGI European Centre Ltd. (currently DIGI Europe Ltd.) in the UK was established. In order to meet the needs of the European food industry marketplace, we established this hub to carry out marketing, product development, and production.  |

| 1993 |  |

Shanghai Teraoka Electronic Co., Ltd. was established in Shanghai, China, as a second development and production hub for Asia. With the aim of responding to the increasingly borderless world economy, and particularly to the Chinese market, which was expected to develop rapidly, we established this hub to undertake marketing, development, and production.  The "FX-3600", which wraps a myriad of items, from trayed products to loose articles, was released. This new type of automatic weigh-wrap-label machine handles a variety of items, from fragile trays to fruits and vegetables without trays, with the same skill as wrapping by hand.  |

| 1996 |  |

The "AW-3600" series automatic weigh-wrap-label system was announced. This is a ground-breaking automatic packaging and labeling machine that realized a major reduction in the amount of film used through a super-stretch technique and automatic tray-size detection function. It also helped eliminate operational errors and improved efficiency.  |

| 1999 |  |

A waste weighing and management system was released. This system precisely managed the disposal of waste by monitoring when, from where, how much, and what type of waste is created. It reinforced reduction of waste generation by providing a "visualization" of the waste.  |

| 2000 |  |

The "ECOA" automatic pure-water vending machine was released. This is an environmentally friendly vending machine that utilizes reusable bottles. It offers local production for local consumption by converting tap water into pure water onsite.  |

|---|---|---|

| 2001 |  |

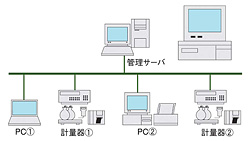

The Service Call Center was established. We established a wide-area call center to serve our customers throughout Japan, and instituted a total management system that uniformly manages the activities of all of our service personnel. The "T@web" total store information system, which shares information via the Internet, was released. Utilizing web technology, this system integrated information generated at the head office, at individual stores, at sales areas in each store, in backrooms, and at POS registers. This was a ground-breaking system that allowed information to be searched and utilized from anywhere.  |

| 2003 |  |

The "SM-4600" retail scale received the "Good Design Award". Following the first "Good Design Award" in the industry in 1959, we have continued to receive awards for our unique features and novel designs.  |

| 2005 |  |

The "SM-4600 ELEXY" retail scale with next-generation display was released. This product allowed eye-contacts between shoppers and store staff over a weighing scale by employing the industry’s first transparent display. It also represented an outstanding example of a next-generation display through its positive effect on the interior design of the sales area.  |

| 2006 |  |

The "Delious" cloud-based integrated food service system for restaurants was released. This product is a cloud-based integrated system that links the floor, kitchen, and main office of a restaurant through uniform data mangement. This unique system by DIGI introduced data management via the Internet well before cloud computing was in general use.  |

| 2007 |  |

The "EZ Series" mobile POS/pre-scanning system was released. This product is a mobile multi-purpose POS terminal that could be used as a mobile store POS register with mobile printer, a self-scanning terminal, or a pre-scanning terminal to eliminate waiting queues when a store is crowded.  The "Saleup" next-generation touch panel ticket vending machine was released. This product is a ticket vending machine with a large-scale touch panel that allows easy customization of product images, key sizes, and screen layouts . It has powerful sales functionality, such as speech guidance, and supports cloud-based networking.  |

| 2010 |  |

The "Checkout Revolution WebSpeeza/Qcashier" was announced. This is a POS system to separate scanning and payment. It improves register productivity by approximately 1.6 times, based on the idea that speed is the best service one can provide to customers.  Environmentally friendly packaging systems were announced. AW-4600e  Non-tray packaging machine  |

| 2011 |  |

The linerless label printer was released. By reducing the size of each printed label to a minimum, it is both ecological and economical. |

| 2013 |  |

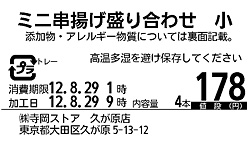

Checkout Revolution 4.0 was announced. ・ Cash management system  The "5600 Series", including a new-generation label printer with user-friendliness, was released. This product employs a large-scale display and a feature for preventing operational errors. It reduces the amount of labels and film used and, by lowering power consumption and it is friendly to consumers, users, and the environment.  The Universal Design (UD) user-friendly font was implemented. Use of a UD font makes printed labels easy to read for consumers, and particularly for the elderly.  |