Picking solution

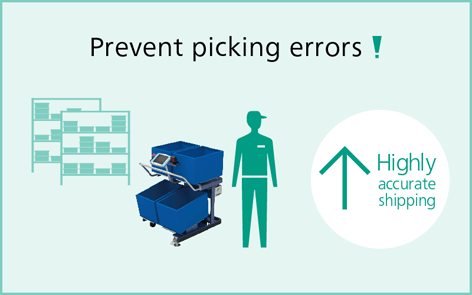

Error rates of zero are in ready reach

Overview

Increase picking accuracy and productivity. Picking routes optimized with algorithm developed by DIGI.

Picking is guided along the shortest path using instructions provided in real time by DIGI's IT-Matex III shipping/receiving management system. At the same time, quantity is verified using scales built into AI picking carts. This not only reduces delivery errors, but reduces staff workload.

Customer Needs

Details

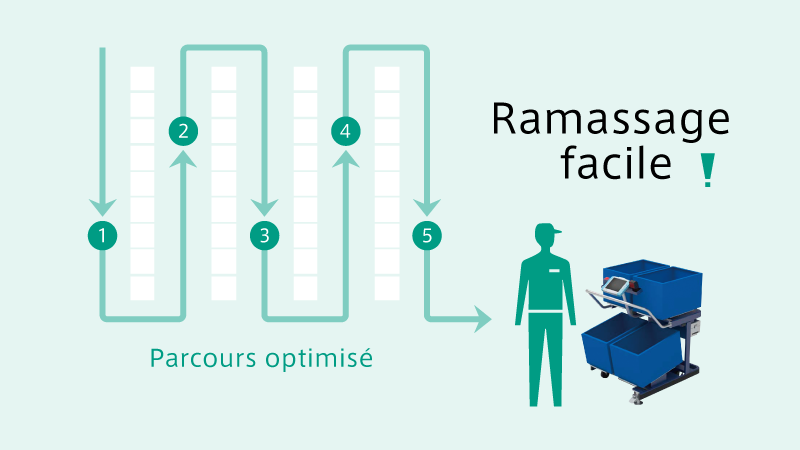

Optimizes work paths and prevents work congestion

A route optimization algorithm developed by DIGI guides picking along the optimal path based on data included in work instructions. This eliminates time spent on wasted movement. At the same time, the algorithm anticipates convergence of workers in individual aisles and makes adjustments to avoid congestion.

Verify quantities simultaneously with picking

Productivity management

Information about picking work is collected in real time, making it easy to grasp cart operational status and progress by individual worker. Paperless analysis of work histories helps cut costs while simultaneously increasing productivity.

Case Studies

Picking accuracy is much higher, giving a big boost to work efficiency

Arata Corporation, Tsukuba Distribution Center

Using artificial intelligence to optimize work paths

A congestion avoidance algorithm calculates optimum picking routes based on order content, reducing distance travelled during picking and eliminating wasted movement.

Accurate multi-picking

Quantities are accurately determined by weighing with the built-in scales, allowing error-free picking of up to 4 orders simultaneously.